One of the joys of ferreting through the Engineer archives is in stumbling upon an article that, while it appears prosaic from its heading and even the accompanying illustration, turns out on closer inspection to contain fascinating nuggets of history. So it was that, while looking through a piece about the early development of the phonograh (which we’ll return to in a later issue) it became apparent that the adjacent article, under the unpromising title of ‘Bent Cranks’, dealt not only with important advances in metallurgy and tooling, but also with a trend in the engineering industry of 1878 that we’re still seeing the effects of today.

In engineering terms, the main thrust of the piece concerns the discovery that, if a material is bent slowly and gradually, it can assume a desired form without adversely affecting the material’s strength or other properties. It notes that iron cranks had previously been made by forging: “a crank was made, chiefly, by hammering, and each successive blow was attended by a change of form, effected in so short a period that it may be considered as without assignable duration, the iron being much distressed by the process.

An alternative approach had come from research carried out by an engineer that the article refers to as ‘M. Tresca’ (Henri Édouard Tresca, a French mechanical engineer who pioneered the study of plasticity in materials in the 1860s and 1870s, and was also one of the designers of the prototype standard metre bar). Tresca had found that the particles of a solid flow when it is distorted, and providing that the distortion is gradual enough, they rearrange to preserve the material’s strength; in a forging made by repeated impact, they do not have time to flow and planes of weakness in the metal may be formed.

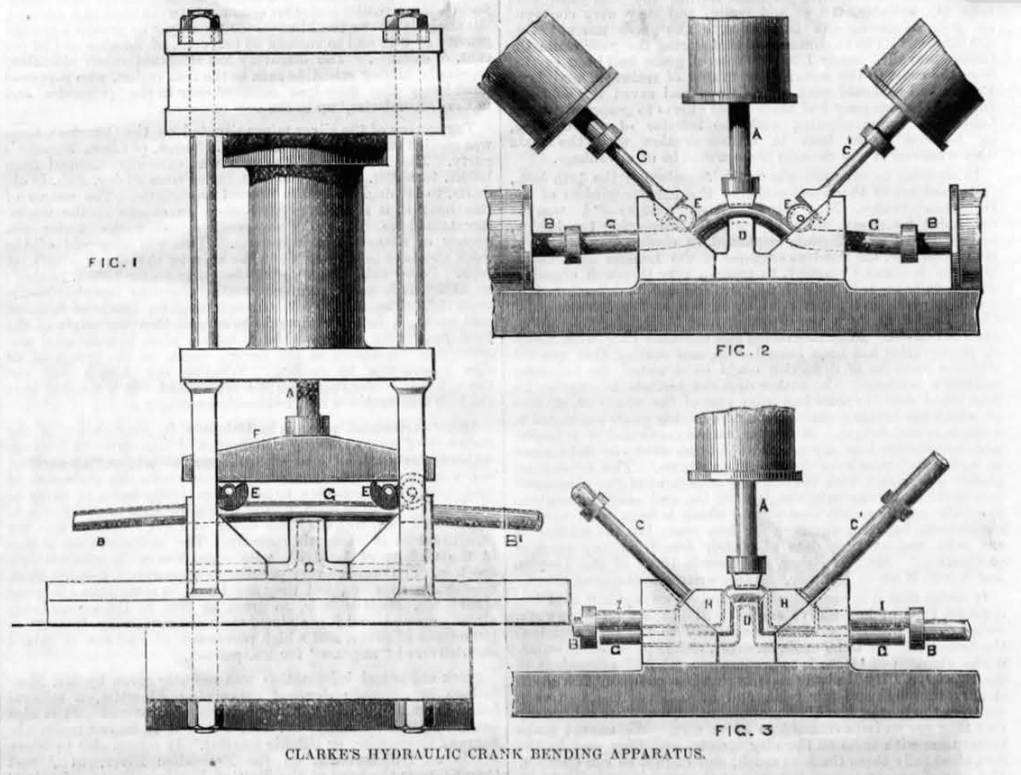

The article then discusses hydraulic crank bending machinery designed by an engineer from Lincoln named Edward Clarke. The device would now seem quite commonplace but it was obviously a surprise to our predecessors. Simply, the device took a bar of iron heated to yellow heat, or of red-hot steel, placed into a die, where one hydraulic ram would press downward on the middle of the bar. Two other rams press on the end of the bar, pushing it into the desired shape. The process took six to eight minutes, during which the hydraulics were in constant motion. ‘The movement is so slow and steady,’ the article says, ‘that it is difficult to observe it, although minute to minute it can be seen that bending has taken place.’

Forging a crank from a 3.5inch iron bar would take a smith and two strikers two and a half to three hours, it says, and so ‘though it may seem paradoxical,’ Clarke’s machine could make cranks in a fraction of the time of conventional forging, and the quality of the product would also be better.

So, we can see here the beginnings to automation rather than hand-making, but the article draws attention to another change in the industry. This, it says, is the rise of the speciality engineering company rather than the ‘general engineering’ firms that had previously dominated the sector, especially in the agricultural engineering industry. ‘The tendency is… to extend the division of labour to entire factories, by limiting the number of sorts of articles being produced.’ This, it continues, reduces the number of draughtsmen needed as well as the amount of tools, and improves the quality of the products. However, it adds, when Clarke founded his factory, ‘very few believed that a manufactory devoted to the production of a single article could be successful,’ and only a very few customers who couldn’t afford their own forging facilities would go to them.

This turned out to be mistaken, however, and ‘a large proportion of the whole of the firms in Great Britain requiring bent cranks… now find that they can buy crank more cheaply and better made than they could produce them at their own works.’ Indeed, at the time of writing Clarke’s Crank Company was about to embark upon an expansion.

The trend of specialism continues today, and Edward Clarke would probably find UK industry’s current preoccupation with high-value manufacturing of specialised machines and components quite familiar. It certainly seems to have worked out: Clarke’s Cranks ceased trading in 2002, and from its ashes was formed Lincoln Crankshaft and Machines (LC&M) in 2003, which still produces large industrial crankshafts, up to 11m long and weighing up to 35tonnes, with 80 per cent of production exported.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...