ABB’s Food and Beverage business, explains why food manufacturers should optimize their processes to reduce energy consumption.

Scientific research has found that temperature can affect the quality of our sleep, with experts advising that it’s best to keep the room at between 18 and 22 degrees Celsius. Similarly, refrigeration plants are required to maintain a specific temperature for the production and storage of products, to ensure and preserve product quality.

Failure to provide the necessary temperature conditions for a food item has a direct influence on the product, which can be hazardous to consumers. For example, in the meat industry, inadequate chilling of cooked meat or failure to maintain the cold chain can lead to microbiological growth, making the product no longer safe for consumption.

To ensure compliance with food safety regulations and reduce the volume of waste in a food processing plant, eliminating the risk of bacterial contamination is at the forefront of every manager’s mind. For refrigeration plants, being able to continuously provide efficient cooling is not only important, it’s an expectation.

The industrial energy problem

Operating all year round to provide the required storage conditions to meet production demands, refrigeration is one of the biggest consumers of energy in a refrigeration plant. From my experience at ABB, refrigeration is responsible for up to 40 to 50 per cent of a manufacturing plant’s energy use.

Currently, the industrial sector accounts for 54 per cent of the world’s total delivered energy. This is more energy than any other end-use sector. Reducing the energy consumption of your refrigeration plant is just one way of cutting production costs and should, therefore, for many plants be made a greater priority to address.

Reducing energy demand and improving efficiency also enhances the life expectancy of equipment. This means the chances of unplanned downtime or interruption to production are reduced and manufacturers can ensure continuous cooling functionality in their plant.

At ABB, we believe the first step to optimizing a refrigeration plant’s energy is by conducting a complete factory assessment. The assessment should include details on the plant’s current operating conditions and the collation of the plant’s measurement and performance data. This information can then be analyzed to improve the overall output and energy usage of the refrigeration plant.

Refrigeration plants firstly need to ensure that they are cooling to the temperature needed and not exceeding the requirements. It’s estimated that for every one degrees Celsius saved, energy consumption is reduced by two per cent.

The overloading of mechanical components, for example the compressor, is one of many regular causes of temperature control system failures. This is usually the result of a process cooling system’s maximum temperature being specified as too low.

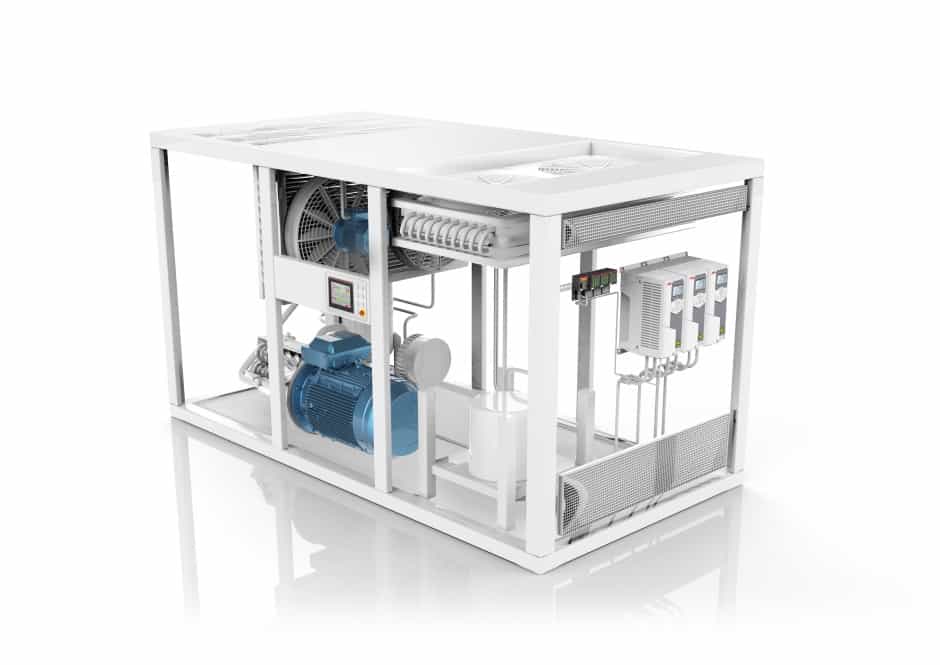

After the energy assessment is complete, we look at where and how energy can be saved. Using variable speed drives (VSDs) and high efficiency motors on distribution pumps, fans, and compressors is one of the most efficient ways to save energy. The control and use of compressors is another area. Cooling towers are another area where using a direct-drive motors and VSDs to replace the traditional shaft and gearbox drivetrain can save not only energy, but also reduce maintenance and even sound levels.

For food manufacturers, the quality of a food product is important, and caution must be given. By taking the necessary steps to optimize a refrigeration plant’s processes, managers will not only reduce their plant’s carbon emissions and utility costs, but also enable it to provide a sustainable temperature across the facility, reducing the product waste as a result.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...