Collapsible structures have many applications, particularly in spacecraft, where the ability to fold structures like antennae and solar panels into a small volume for launching but still have it unfold once deployed into a strong, rigid structure is invaluable. Nature, as so often, provides inspiration, and insects are the undoubted masters of this trick, with lightweight wings that can collapse and fold into small spaces and yet unfold into structures stiff and strong enough to support and propel the animals in flight.

Researchers at the University of Tokyo have now uncovered how ladybirds (locally known as ladybugs) stow their wings. These particular common beetles were chosen because of the speed with which they can unfold and deploy their wings.

Like most beetles, ladybirds have two sets of wings. The forward set, called elytra, are a hard material and act as protection for the more delicate underling rear set which the insect uses for flying. The Tokyo team, led by Professor Kazuya Saito of the university’s Institute of Industrial Science, wanted to investigate the roles played by unusually complex origami-like folds in the wings, thick veins in comparison to their size, and up-and-down motions of the insect’s abdomen that had been observed previously.

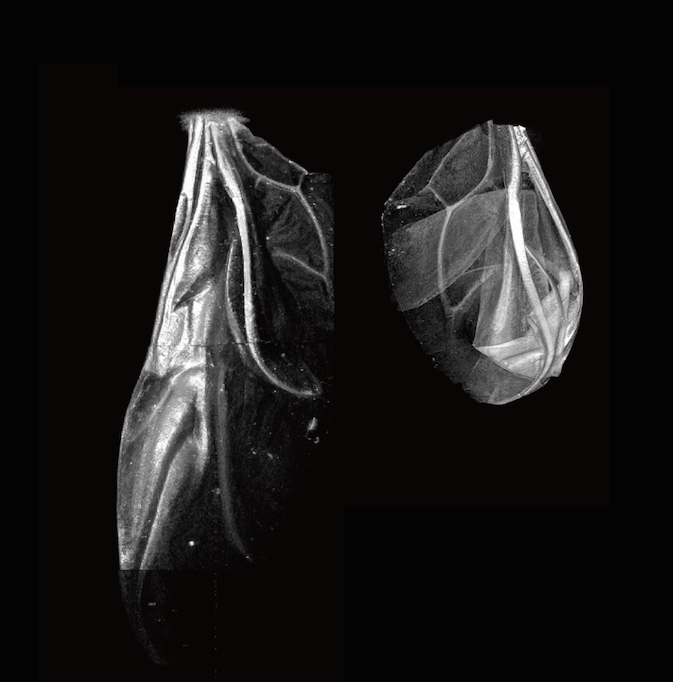

One problem was that the folding of the rear wing is connected to the opening and closing of the elytra. To get around this problem, the team anaesthetised a ladybird, removed one elytron and cast a replica of it from transparent resin – the same kind used in fingernail art. They then stuck this transparent elytron onto the stub of the removed wing-case and observed the insect using high-speed cameras and micro-CT scanning. "I wasn't sure if the ladybug could fold its wings with an artificial elytron made of nail-art resin," said Saito. "So I was surprised when I found out it could."

The team found that the insects use the edges and lower surfaces of the elytra to guide the folding of the underwing, which happens mostly after the elytra are closed. The CT scanning revealed that the veins in the wings have a curved shape similar to that of a steel retractable measuring tape (also known as a tape spring) that give rise to rigid points in the wing which can become flexible, and along which the wing can fold up. "The ladybugs' technique for achieving complex folding is quite fascinating and novel, particularly for researchers in the fields of robotics, mechanics, aerospace and mechanical engineering," said Saito.

In a paper in the journal Proceedings of the National Academy of Sciences, Saito and team explain how this discovery could have implications for the design of robots, elements of buildings and lightweight collapsible structures

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...