Described in the online version of Nature Materials, the new material could enable highly precise, self-adjusting contact lenses that clean themselves, or pipelines that optimise the rate of flow depending on the volume of fluid coming through them and the environmental conditions outside.

‘The beauty of this system is that it’s adaptive and multifunctional,’ said senior author Joanna Aizenberg, PhD, a Core Faculty member at the Wyss Institute and the Amy Smith Berylson Professor of Materials Science at SEAS.

The new material was inspired by dynamic, self-restoring systems in nature, such as the liquid film that coats eyes. Individual tears join up to form a dynamic liquid film with an obviously significant optical function that maintains clarity, while keeping the eye moist, protecting it against dust and bacteria, and helping to transport away any wastes.

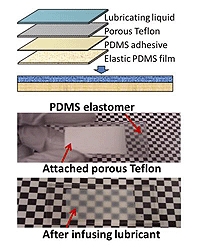

The bioinspired material is a continuous liquid film that coats, and is infused in, an elastic porous substrate. It is based on a core concept: any deformation of the substrate – such as stretching, poking, or swelling - changes the size of the pores, which causes the liquid surface to change its shape.

With this design architecture in place, the team has so far demonstrated the ability to dynamically control two key functions: transparency and wettability, said Xi Yao, Ph.D, Wyss Institute and SEAS postdoctoral fellow, and lead author of the study.

Sitting at rest, the material is smooth, clear and flat; droplets of water or oil on its surface flow freely off of the material. Stretching the material makes the fluid surface rougher, Yao said in a statement.

The rough surface makes it opaque, which offers the ability to make every droplet of oil or water that is placed on it reversibly start and stop in their tracks. This capability is far superior to the ‘switchable wettability’ of other adaptive materials that exist today, Yao said, which switch between hydrophobic to hydrophilic.

‘In addition to transparency and wettability, we can fine-tune basically anything that would respond to a change in surface topography, such as adhesive or anti-fouling behaviour,’ Yao said in a statement. They can also design the porous elastic solid such that it responds dynamically to temperature, light, magnetic or electric fields, chemical signals, pressure, or other environmental conditions.

The material is a next generation of a materials platform that Aizenberg pioneered a few years ago called SLIPS (Slippery Liquid-Infused Porous Surfaces) that repels just about anything with which it comes into contact, including oil, water, and blood.

SLIPS is a liquid-infused rigid porous surface. ‘The new material is a liquid-infused elastic porous surface, which is what allows for the fine control over so many adaptive responses above and beyond its ability to repel a wide range of substances. A whole range of surface properties can now be tuned, or switched on and off on demand, through stimulus-induced deformation of the elastic material,’ Aizenberg said.

Project to investigate hybrid approach to titanium manufacturing

Sadly they will not be ordering any more presses from Wilkins & Mitchell http://www.historywebsite.co.uk/articles/Darlaston/WM.htm