Funded through an EPSRC Sustainable Manufacturing grant, the project is pushing to lower emissions within UK manufacturing and help the UK reach its 2050 Net Zero targets.

Leading the research is principal investigator Dr Jin Xuan, professor and head of the Department of Chemical Engineering at Loughborough University, and director of the UKRI Interdisciplinary Centre for Circular Chemical Economy.

Professor Xuan told The Engineer that the UK chemical manufacturing sector has an annual turnover of £32bn, but is also one of the top emitting sectors of CO2.

“If we can develop a net zero emission manufacturing system, that will contribute a lot to the UK’s economic success,” Xuan said. “Also, the biomanufacturing sector itself represents a huge opportunity for clean growth.”

Comment: How we can all profit from a circular economy

Manufacturing faces rocky road to net zero

Biomanufacturing involves using biological substances as feedstock within the manufacturing process to make value-added chemicals and materials for sustainable bioproducts, Xuan explained, such as medicines, polymers and detergents.

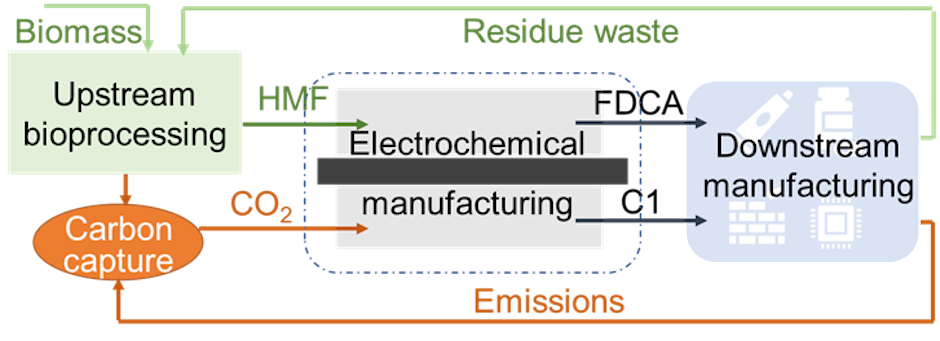

Whilst the process is sustainable - it utilises waste such as biomass as feedstock - it still releases carbon dioxide. Waste from the end products at end-of-life will either be incinerated or go to landfill.

“We want to capture the carbon dioxide and put it back into the manufacturing process, eliminate waste after the end-of-use of the product and put it back in as a feedstock,” Xuan said. “Through this closed-loop circular economy design, we want to eliminate all forms of carbon loss.”

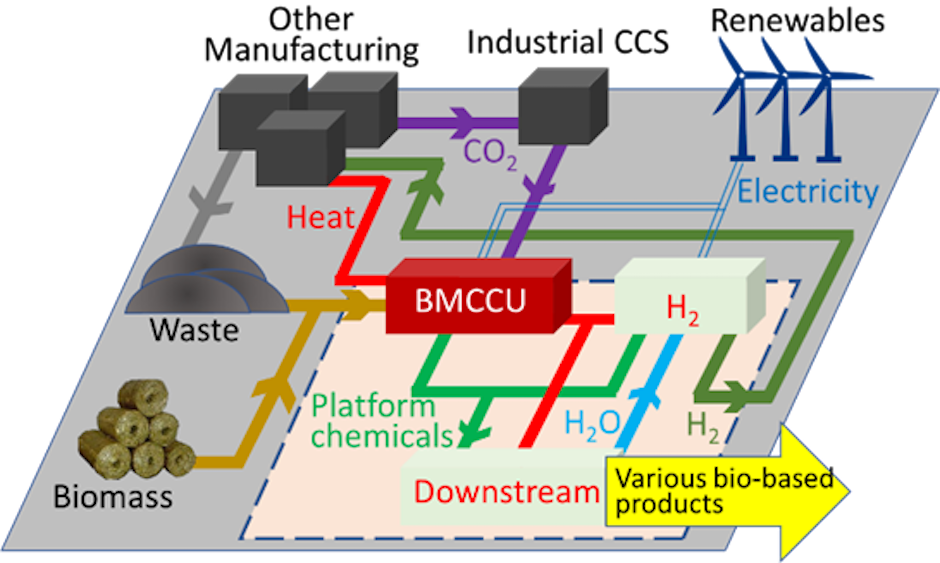

The project’s unique factor is the use of an electrochemical process to capture and utilise carbon, he added, driven by renewable energy. Development of the novel BMCCU (biomanufacturing with carbon capture and utilisation) process, integrating electrochemical lignocellulosics conversion with CO2 reduction, can save up to 50 per cent of energy and double the resources and yield of value-added products, according to the team.

Construction of an interoperable digital twin will also be a key element of the project, enabling self-optimisation regarding objectives and constraints such as cost, quality, yield, sustainability, and scalability.

“We want to embed the digital twin technology because once we have the electrochemical process developed, we want to integrate it into wider biomanufacturing systems,” Xuan said. “This involves understanding the very complex dynamics of the manufacturing system.”

A digital twin built for every unit within the manufacturing process will reflect what is happening in the physical assets to allow for dynamic control of the system, he explained, with the challenge being how to optimise the system against uncertainties.

The project will take a whole system approach to tackle engineering problems as well as addressing wider economic, social and environmental challenges for sustainable evolution of bio-based industries.

In addition to collaborating with academic partners from Imperial College and Heriot-Watt University, the project involves partners including the Knowledge Transfer Network (KTN), BASF, the Manufacturing Technology Centre (MTC) and Oxford University spin-out OxCCU.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...