Fibre such as this could have applications in robotics, prosthetics or even in clothing that automatically adjusts to fit.

Nylon artificial muscle fibres appear to have a property that has so far eluded other artificial muscle fibres: they can reproduce the bending motion of fingers and limbs. Moreover, the fibre can do this alone, with no need for extra mechanical pulleys or wheels.

The key to the properties is the way the fibre is shaped and heated. In a paper in the journal Advanced Materials, Prof Ian Hunter and Seyed Mirvakili, a PhD student, describe how they found and developed the specific properties of nylon fibre. Previously, artificial muscle fibre research had used nylon in twisted and coiled filaments to mimic the basic linear activity of muscles; contracting and expanding in a straight line. The systems could not bend, however. Fibres capable of reproducing bending motion tend to use "exotic materials to do the job, and they are very difficult and very expensive to make," Mirvakili said. These materials include carbon nanotubes fibres, which are too expensive for widespread use, and shape memory alloys, which break after relatively few expansion-contraction cycles.

Mirvakili's discovery hinges on an unusual property of oriented nylon fibre: when heated, it shrinks in length but becomes wider. One problem with this, which has caused difficulties when using this property in the linear actuators, for example, is that nylon stores heat quite well and cools down slowly. "The cooling rate can be a limiting factor, but I realise it could be used to advantage," said Mirvakili. If one side of the fibre is heated, it contracts on that side only, because the heat doesn't have time to penetrate all the way through the fibre. The fibre therefore bends towards the heat source. "You need a combination of these properties," he explained. "High strain (the pull of the shrinking motion) and low thermal conductivity."

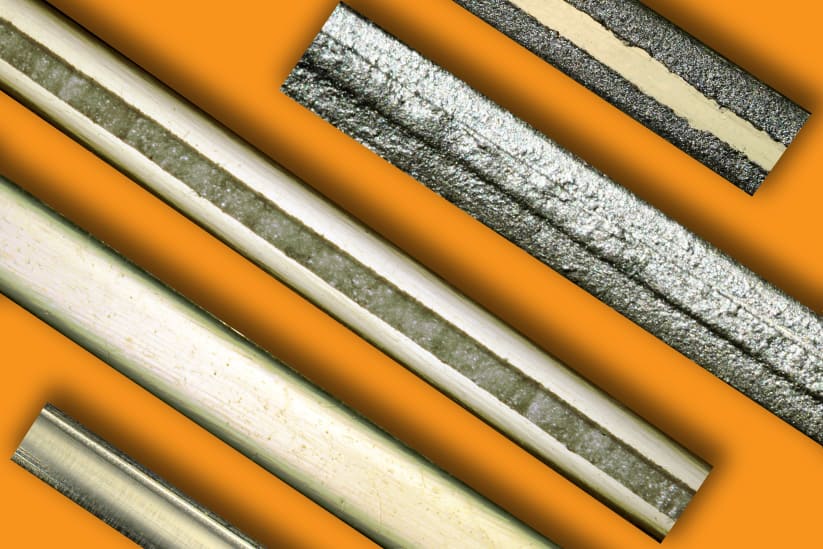

To harness this property, the fibre needs to be shaped. Fortunately, complex geometry is not needed; a square or rectangular cross-section will do, and this can be achieved by simply squashing a standard circular-diameter length of nylon fishing line. A variety of techniques can be used to heat the fibre on one side: these can include lasers, chemical reactions or electrical resistance heating, for example. One method the MIT team found successful was coating one side of the fibre with conductive paint and a resin binder and passing a current through it. These coated fibres can maintain the performance over 100,000 bending cycles, and can perform 17 cycles per second. Moreover, changing the direction of the heating can cause the fibre to move such that its end describes circles and figures of eight.

According to Prof Hunter, applications for this might include clothing that can adjust itself to fit, reducing the number of sizes that manufacturers would need to make, and self-tightening shoes. Less trivially, the fibre could be used in self adjusting catheters and biomedical devices, automotive panels that can change shape to improve aerodynamics, or systems to help solar panels track the sun using the sun's heat to produce the movement. There are also applications in robotic grippers, microscopic tools, and machine components.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...