Lloyd’s Register has announced the first certification of a part produced through additive manufacturing (AM) for the oil and gas industry.

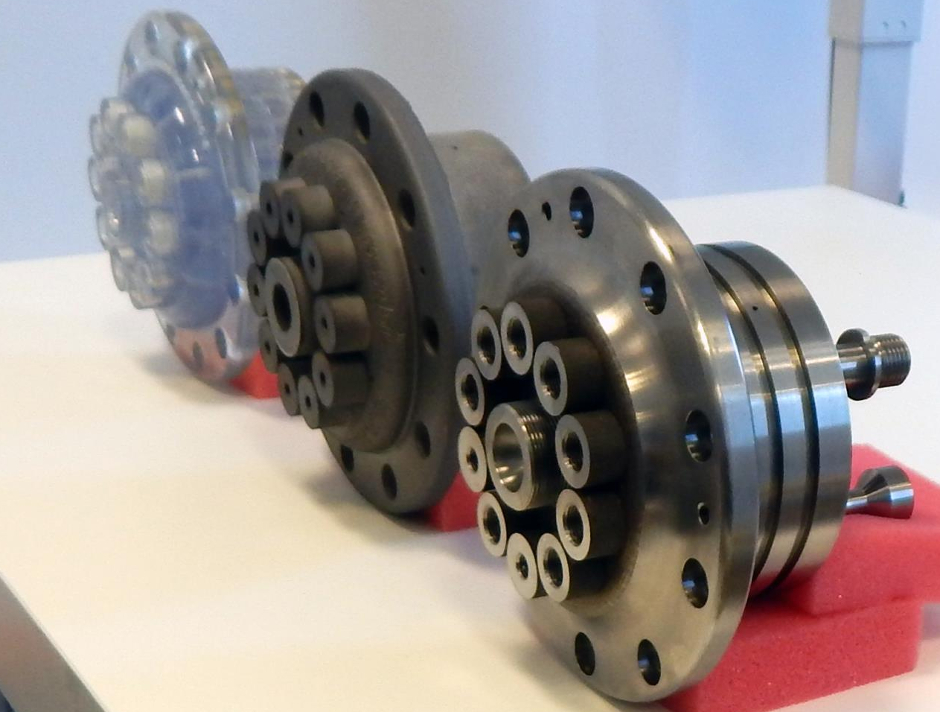

The titanium gateway manifold for pipelines was designed by Surrey-based Safer Plug Company (SPC) and built by 3T RPD using powder bed fusion. The entire process was overseen and certified by Lloyd's Register (LR).

SPC approached LR over a year ago in order to provide independent assurance of the manifold’s manufacture, due to the process it went through to design and produce it. The manifold is to be included in an assembly for a suite of pipeline isolation tools, which will reportedly include the world’s smallest tool suitable for six-inch diameter pipework.

“This project is a great example of how innovative companies are making great use of additive manufacturing’s benefits,” said Amelia Stead, LR AM Surveyor and the primary technical lead on the project. “This part would have been nearly impossible to produce using traditional manufacturing techniques due to its complex internal channels.”

LR’s framework, which guides manufacturers on AM processes to certify components and produced alongside The Welding Institute (TWI), manufacturing facilities as well as material standards.

LR will also certify the next batch of 10 manifolds produced by SPC and 3T RPD. SPC is now working with LR on a Type Approval certificate which would allow it and 3T RPD to produce the manifolds on demand, as well as the pipeline isolation tools.

“From an industry and customer perspective this certification provides added confidence in parts produced by this new technology,” said Dr Claire Ruggeiro, Director Innovation, Technical and Quality for LR. “This will undoubtedly accelerate the adoption of AM into the oil and gas mainstream. The work we have done with TWI and research undertaken by the LR Foundation-funded PhD students has provided the robust basis for this certification and we look forward to further building our expertise and experience together with the industry pioneers like SPC.”

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.