It’s the sound every mechanic and technician dreads: the shriek of misaligned gears that tells you that something is very wrong in the gearbox. It heralds a probable equipment breakdown, outages and expensive repairs.

But this could be a thing of the past, according to researchers from Universidad Carlos III de Madrid, who have developed a transmission mechanism where none of the mechanical parts touch each other. Working by magnetism, the transmission system needs no lubrication and is immune to damage by wear and friction.

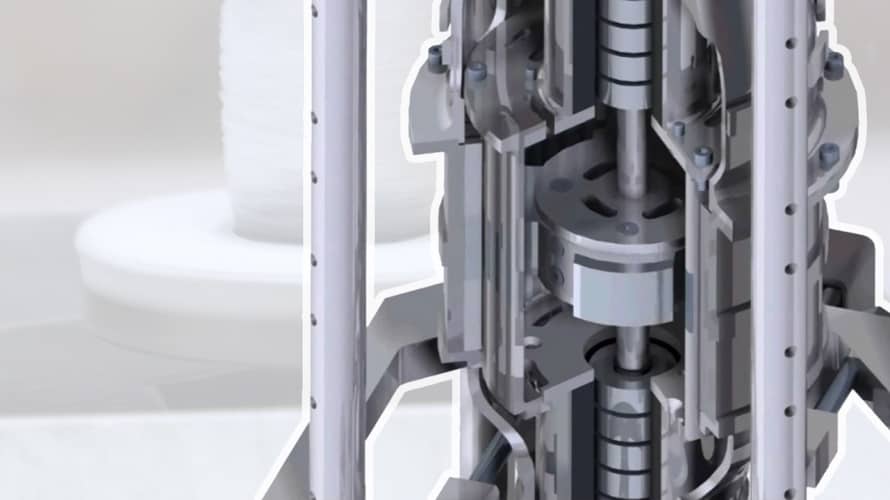

Developed under a European research project called MAGDRIVE, the system is essentially a magnetic gear reducer: in other words, it transforms the rotational speed of an input axle to a different speed of an output axle.

It does this without using toothed gears at all: as researcher Efrén Díez Jiménez explained, ‘it substitutes geared teeth with… magnets that repel and attract each other so that the transmission of couples and forces between the moving parts with contact is achieved.’

The stated goal of MAGDRIVE, which included four research institutions and three companies, was to develop a transmission system which could work at extremely low temperatures in space, such as in robot arms or antenna or solar panel positioners, or robotic rovers; these require high precision movements and a lack of contamination from lubricants.

However, the Madrid team has developed two prototypes: a cryogenic one, which works at -210°C and can operate in a vacuum, and another which uses permanent magnets at room temperature.

The cryogenic version integrates levitating superconducting bearings that generate stable forces of repulsion into its structure. This both allows it to turn and stabilises it against oscillating motion and imbalances.

‘It is the first time in history that the input axle as well as the output axle of a gear reducer are floating without any kind of contact, and it can keep a mechanism which contains nothing else spinning at 3,000 revolutions per minute at cryogenic temperatures,’ said team leader, José Luis Pérez Díaz.

The team expects that the room-temperature version will find more applications than the low-temperature type. Owing to the absence of lubricants, it might be particularly useful in production machinery in industries where cleanliness is paramount, such as pharmaceuticals, food and biomedicine, although it can also be used in railways, oil and gas, and any propulsion system.

Results have been published in the Journal of Engineering Tribology and a paper is upcoming in the journal Aerospace Science and Technology, while the researchers from the seven partners have formed a spin-out company called MAG SOAR to commercialise the research.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...