The source of this interruption to services can be found in the leaves falling onto railway lines and being turned into a Teflon-like mulch by trains passing over them.

Consequently, this slippery coating requires train drivers to brake earlier when approaching stations and signals, then accelerate cautiously to avoid wheel spin.

The situation is so pronounced that annual timetable adjustments are made, a situation that London-based Imagination Factory hopes to alleviate with bursts of microwave energy to dry out a section of the track.

In 2014 the company was one of seven organisations awarded funding by the Rail Safety and Standards Board (RSSB) to take forward its solution as part of the 'Predictable and Optimised Braking Challenge'.

The company’s solution, which has completed an early proof of concept feasibility study, would see microwave energy directed at railway tracks during braking.

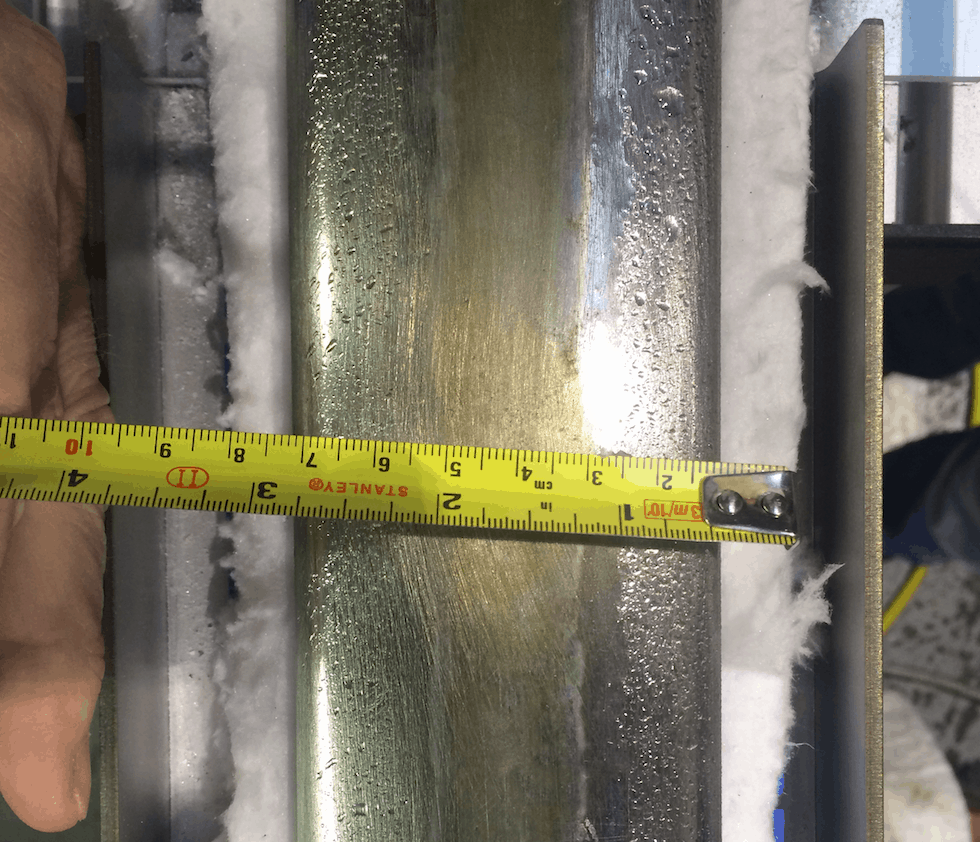

Julian Swan, engineering lead and co-founder of Imagination Factory, said the idea is to dry the contact patch between the rail and wheel interface, which is approximately 12mm wide.

“We are not intending to dry the full track width,” he said via email. “Our design vision is to have a modular approach to enable us to treat the tracks individually and progressively down the length of the train.”

For the microwave element, Swan explained that the initial Proof of Concept rig operated at 6kW using an 896MHz source but that in the next phase of development the company will investigate 2.3GHz as this has the potential to improve energy density and component compactness.

Furthermore, Imagination Factory proposes separating the power electronics from the microwave generation by the use of coax cabling.

“This will enable us to locate some of the larger more sensitive pieces of equipment on the sprung chassis of the carriage and the more robust solid state elements of the microwave antenna can be located near the wheel,” said Swan. “This flexible modular build principle should enable the final design to be retrofitted as well as incorporated in new build.”

So far, scale tests have been completed at 1mph but Swan added that the company’s mathematical model suggests a linear relationship enabling full effect at up to 50mph.

“We are hoping to demonstrate this during the next Phase of funded development through the RSSB,” he said. “Additionally, the energy used for the system during braking could also be created by regenerative braking. Currently regen brakes are not able to return the energy to the grid due to the quality of what is created. This system could utilise this energy easily”

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...