The milliDelta robot, reported in Science Robotics, was developed by Robert Wood's team at Harvard's Wyss Institute for Biologically Inspired Engineering and John A Paulson School of Engineering and Applied Sciences (SEAS).

By integrating their microfabrication technique with high-performance composite materials that can incorporate flexural joints and bending actuators, the milliDelta can operate with high speed, force, and micrometre precision, reportedly making it compatible with a range of micromanipulation tasks.

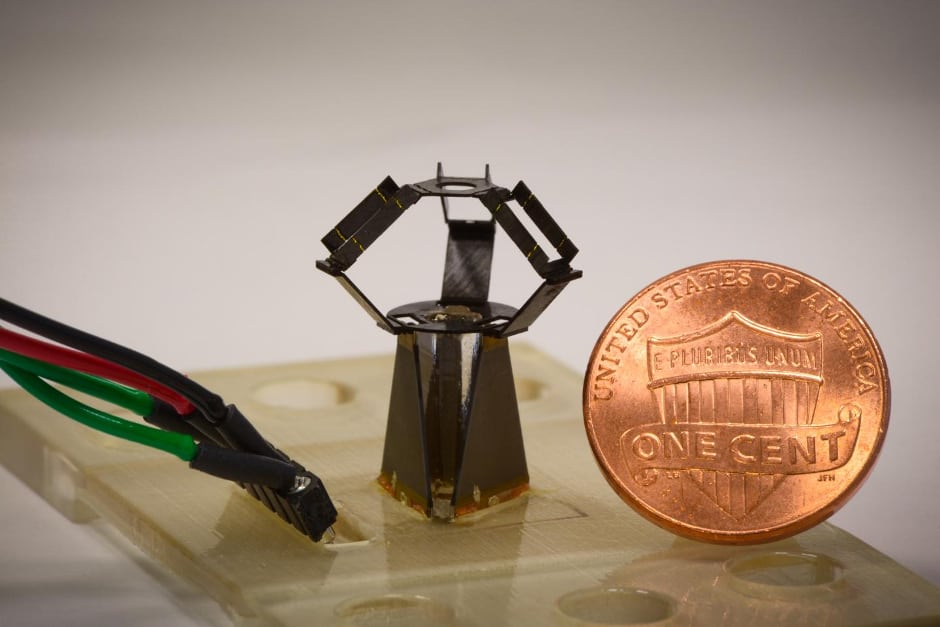

In 2011, inspired by pop-up books and origami, Wood's team developed a micro-fabrication approach that enables the assembly of robots from flat sheets of composite materials. Pop-up MEMS (microelectromechanical systems) manufacturing has since been used for the construction of dynamic centimetre-scale machines that can walk away, or fly, as seen with RoboBee, can fly. In their new study, the researchers applied their approach to develop a Delta robot measuring 15mm-by-15mm-by-20mm.

"The physics of scaling told us that bringing down the size of Delta robots would increase their speed and acceleration, and pop-up MEMS manufacturing with its ability to use any material or combination of materials seemed an ideal way to attack this problem," Wood said in a statement. "This approach also allowed us to rapidly go through a number of iterations that led us to the final milliDelta."

The milliDelta design is said to incorporate a composite laminate structure with embedded flexural joints that approximate the more complicated joints found in large-scale Delta robots.

"With the help of an assembly jig, this laminate can be precisely folded into a millimetre-scale Delta robot. The milliDelta also utilises piezoelectric actuators, which allow it to perform movements at frequencies 15 to 20 times higher than those of other currently available Delta robots," said first-author Hayley McClintock, a Wyss Institute Staff Researcher on Wood's team.

In addition, the team demonstrated that the milliDelta can operate in a workspace of about seven cubic millimetres and that it can apply forces and exhibit trajectories that, together with its high frequencies, could make it suitable for micromanipulations in industrial pick-and-place processes and microscopic surgeries such as retinal microsurgeries performed on the human eye.

Putting the milliDelta's potential for microsurgeries and other micromanipulations to a first test, the researchers explored their robot as a hand tremor-cancelling device.

"We first mapped the paths that the tip of a toothpick circumscribed when held by an individual, computed those, and fed them into the milliDelta robot, which was able to match and cancel them out," said co-first author Fatma Zeynep Temel, PhD, a SEAS Postdoctoral Fellow in Wood's team.

The researchers think that specialised milliDelta robots could either be added on to existing robotic devices or be developed as standalone devices.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.