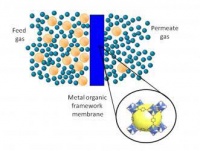

MOF membranes offer an alternative to more energy-intensive processes for separating gases such as carbon dioxide, methane, nitrogen and hydrogen. The technology has generated significant interest because of the range of crystalline structures that can be synthesised, but development of new MOF membranes is still at an early stage.

’Metal-organic framework membranes will be useful for doing large-scale energy-related separations in an efficient way,’ said David Sholl, a professor in the Georgia Tech School of Chemical and Biomolecular Engineering. ’A lot of chemists are interested in developing these metal-organic frameworks and we hope to provide a new approach to designing the membranes.’

Metal-organic framework materials are nanoporous crystals that combine metal-organic complexes with organic linkers to create highly porous frameworks. They offer advantages such as high surface area, porosity, low density and both thermal and mechanical stability - all important for separation membranes.

There are many possible material combinations that could be used in the membranes. By comparing such properties as binding strength and flow rates, the computational modelling could give researchers a way to rapidly identify the materials that will work best in high-volume industrial applications.

’The extra challenge with using metal-organic frameworks is that there are literally thousands of different materials that could be considered for use,’ said Sholl. ’This is where computational modelling really helps. We are doing the materials screening problem computationally to guide us in attacking the actual fabrication problem experimentally.’

Sholl hopes the technique will narrow the list of candidate materials from thousands down to as few as 10. Researchers would then fabricate the membranes and test them in real-world conditions.

’If we were testing all of these in the lab without the computational guidance, it’s unlikely that we would ever choose the right material,’ he said. ’The biggest challenge for making a new membrane is that it really requires a lot of work to make a functioning device. Even if we know exactly what material to use, there is a very long development path.’

At Georgia Tech, Sholl’s modelling group is working with experimentalists such as Sankar Nair and Christopher Jones - both professors in the School of Chemical and Biomolecular Engineering - to produce prototype membranes for evaluation.

In addition to colleagues at Georgia Tech, the group is also working with industrial partners to help ensure that the membranes work in industrial conditions.

’If we can go from the idea in the academic lab to a serious field test within five years, this would be a real success,’ said Sholl.

The researchers have already modelled how the membrane technology would operate in separating methane from carbon dioxide, hydrogen from carbon dioxide, nitrogen from carbon dioxide, hydrogen from methane, nitrogen from hydrogen and methane from nitrogen.

Viking Link connects UK and Danish grids

These underwater links must, based on experience with gas pipelines, be vulnerable to sabotage by hostile powers. Excessive dependency on them could...