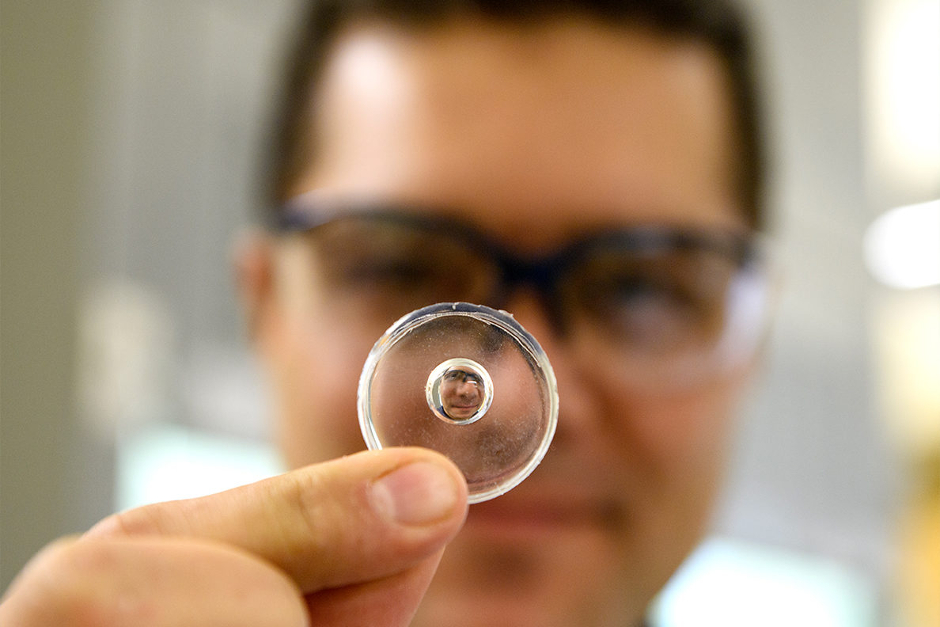

Researchers have developed a low-cost method of making custom lenses that could help manufacturers avoid expensive moulds required for low-volume optical manufacturing.

Led by Lei Li, assistant professor in Washington State University’s School of Mechanical and Materials Engineering, and graduate student, Mojtaba Falahati, the researchers developed a liquid mould from droplets that they can manipulate with magnets to create lenses in a variety of shapes and sizes. Their work is featured in Applied Physics Letters.

According to Washington State, the traditional moulding and casting processes used in the manufacture of high-quality lenses require complex and expensive metal moulds, limiting manufacturers to mainly mass producing one kind of lens.

The team, including researchers from Ohio State University, encountered the problem when they searched for lenses during work to develop a portable laboratory reader on a phone.

They first tried to make their own lenses using 3D printing but found it difficult to control the lens shape. They then came up with the idea of using magnets and the surface tension of liquids to create free-flowing moulds.

They placed iron particles into liquid droplets and built a device to surround the droplets with magnets. They then poured the plastic material used in lenses over the droplet. As they applied a magnetic field, the droplet took on a conical lens shape – creating a mould for the plastic lens material. Once they cured the plastic, it hardened and had the same optical properties and imaging quality as a commercially purchased lens. The liquid droplet remains separate and can be re-used.

Washington State added that the magnets can be moved to change the magnetic field, the shape of the mould, and the resulting lens. The researchers also used bigger or smaller droplets to create lenses of varying sizes.

“We brought the concept of interfacial tension to the field of optics by introducing an innovative controllable liquid mould,” said Li. “This novel process allowed us to regulate the shape of a magnetic drop and to create lenses without having to fabricate expensive moulds.”

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...