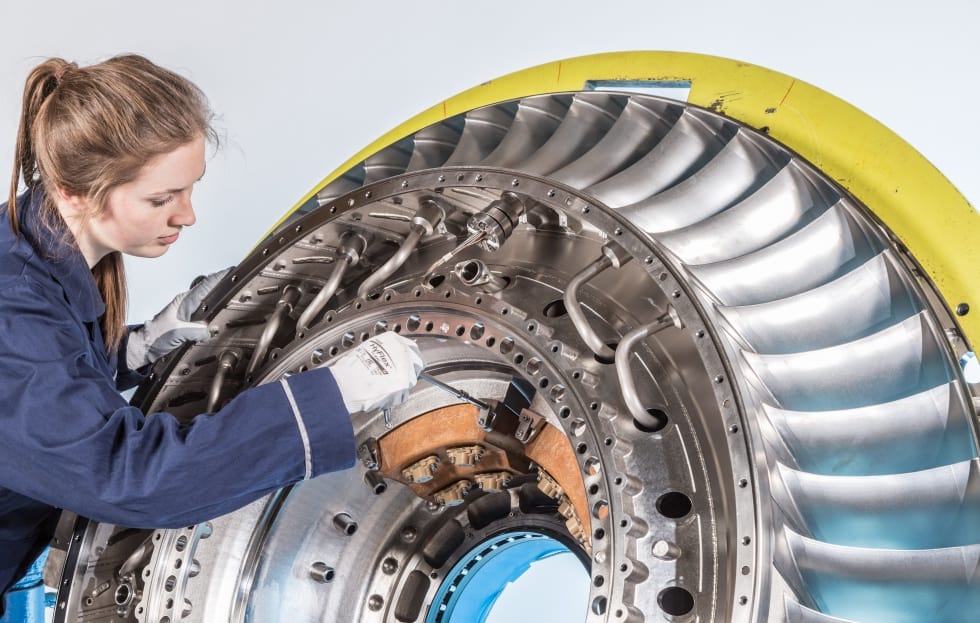

The new contracts, which are said to create and secure jobs at the company’s Pinxton plant, enter Nasmyth Bulwell into long-term agreements for legacy and new components.

These are destined for engines including the Rolls-Royce XWB and Trent 1000 which are installed on Airbus and Boeing’s new wide body airlines.

Peter Smith, chairman and CEO of Nasmyth Group said: “We believe the new contracts are a huge vote of confidence in Nasmyth’s complex capabilities as solutions providers. We are continuing to invest heavily in the latest manufacturing technology and in the skills of our growing 260 strong workforce to ensure we remain competitive in the global aerospace, defence and nuclear markets.”

Nasmyth Bulwell’s success follows its work with Sharing in Growth (SiG), the government-backed programme to raise the productivity and competitiveness of the UK aerospace supply chain.

Nasmyth Bulwell joined the programme in 2014 and has since increased its turnover from £24m to around £30m and hired 20 engineers, operators and apprentices.

The company is now spending £2.2m on installing equipment that includes both 4 and 5-axis milling machines complimented by two turning centres.

“The investments underpin the current expansion plans of the business and enhance the technical capabilities of Nasmyth Bulwell”, said Eddie Jones, director of Nasmyth Metallics Bulwell and Arden.

Andy Page, SiG’s CEO added: “Nasmyth Bulwell’s investment in people and technology is paying off and its growth plans are being realised.

"Our aim is to support the UK aerospace supply chain to reduce costs and become more productive so that they can secure contracts and jobs in the highly competitive global market.

"SiG is already helping more than 50 companies achieve their aim of an average 50% increase in productivity and is targeting an average 20 per cent cost reduction.”

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...