The work, published in the journal Nature, describes a porous and flexible material known as a metal-organic framework (MOF), which undergoes a dramatic structural change when it adsorbs methane. The MOF collapses when the methane is extracted to run the engine, but expands when the natural gas is pumped in at only moderate pressure.

There are currently more than 150,000 compressed natural gas (CNG) vehicles on the road in the United States, the majority of which are buses and trucks. Today’s CNG vehicles compress natural gas into an empty tank under 250 atmospheres (3,600 psi), whereas the flexible MOF can be loaded with methane at 35 to 65 times atmospheric pressure (500-900 psi) - a significantly less extreme pressure to operate at.

“You could potentially fill up at home,” said Jeffrey Long, a UC Berkeley professor of chemistry who led the project.

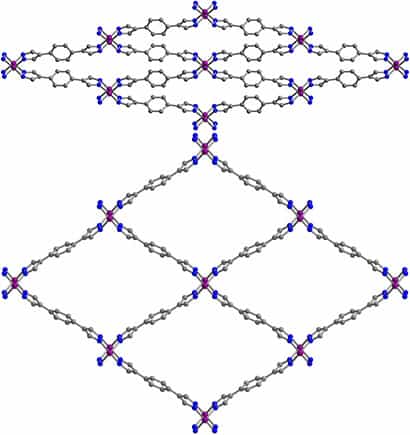

The flexible MOFs the team tested are based on cobalt and iron atoms dispersed throughout the structure, with links of benzenedipyrazolate (bdp). Both cobalt (bdp) and iron (bdp) are highly porous when expanded, but shrink to essentially no pores when collapsed. As well as its storage benefits, flexible MOFs also require less cooling than other methane absorbers.

“If you fill a tank that has adsorbent, such as activated charcoal, when the methane binds it releases heat,” said Long. “With our material, some of that heat goes into changing the structure of the material, so you have less heat to dissipate, less heat to manage. You don’t have to have as much cooling technology associated with filling your tank.”

According to Long, the first experiments on these compounds already surpass the theoretical limits for rigid MOFs, but a lot of work is required before the technology is vehicle-ready.

“This is a fundamental discovery that now needs a lot of engineering to find out how best to take advantage of these new adsorbent properties,” he said.

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...