The FlySafe collaboration, which is being led by engineering consultancy Ricardo, includes the University of Brighton’s Centre for Automotive Engineering, alongside Imperial College London, Torotrak Group and GKN Hybrid Power.

Flywheels offer a potentially clean and cost-effective method of storing energy, and are currently used to save fuel and reduce emissions in vehicles through applications such as regenerative braking.

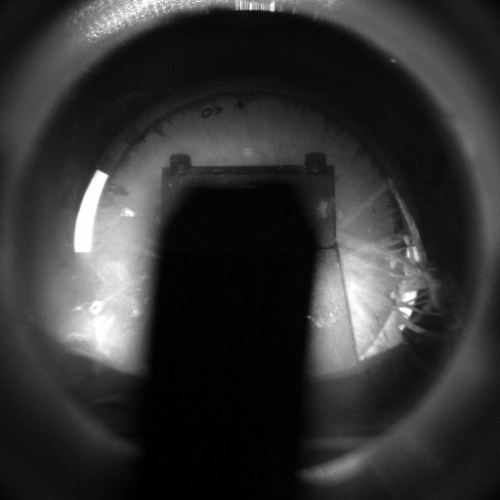

The team is using a custom-built test rig to analyse flywheel operation, investigating potential failure mechanisms at rotational speeds of up to 60,000 RPM in a vacuum. Imaging and sensors are used to monitor the behaviour of flywheels when they are caused to fail at high speeds through deliberately engineered defects.

Video is shot with a high-speed system that captures 20,000 frames per second, synchronised with a high-intensity pulsed laser that illuminates the flywheel. According to Ricardo, this high frame rate allows for just two seconds of footage to be captured, so data indicating when failure is imminent is closely monitored in order to film the exact moment it occurs.

“High-speed flywheel energy storage technology can provide a very practical, effective and commercially attractive means of saving energy, fuel and hence CO2 emissions across a range of industries,” said David Rollafson, Ricardo vice president of innovation.

“A major challenge in designing compact and lightweight high-speed flywheel systems, however, is in the provision of safety containment systems. In the absence of detailed data on potential failure mechanisms, these previously have had to be very conservatively engineered.”

The team hopes that the research will provide “fundamental understanding of the failure processes in composite flywheels”, and a key output of the project will be a proposed BSI flywheel safety standard.

“The meticulous and detailed research being carried out on the FlySafe project and the existence of the test facility at the University of Brighton, will enable the partners to propose a BSI flywheel safety standard to promote a higher level of design optimisation while retaining the full required safety level,” continued Rollafson.

“I believe that these achievements of FlySafe will accelerate the commercialisation of this very promising environmentally friendly technology across a range of industry sectors.”

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...