Common solar cells found on rooftops or in solar farms are typically made from silicon. But their production can be energy intensive, and silicon cells are generally heavy and difficult to transport. Many alternative thinner film cells use toxic element such as cadmium, or contain scarce elements such as indium or tellurium.

In contrast, the semi-transparent AgBiS2 cells use non-toxic, earth-abundant elements, produced in ambient conditions. This combination should make them both greener and safer than current technologies.

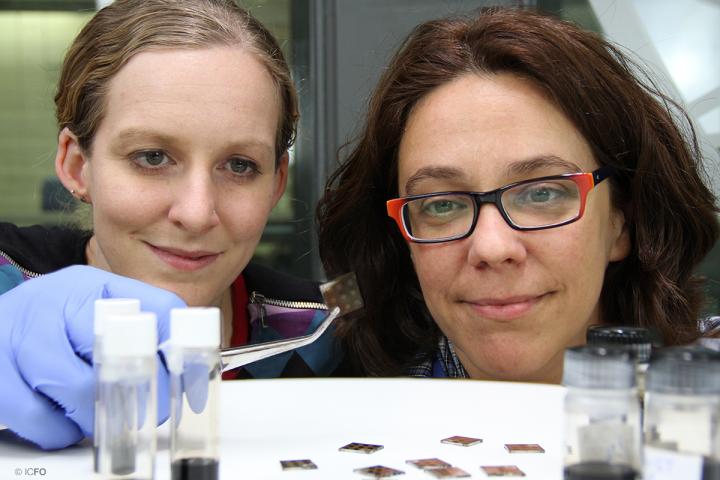

"A very interesting feature of AgBiS2 solar cells is that they can be made in air at low temperatures using low-cost solution processing techniques without the need for the sophisticated and expensive equipment required to fabricate many other solar cells,” said Dr Nicky Miller, one of the research leads.

“These features give AgBiS2 solar cells significant potential as a low-cost alternative to traditional solar cells."

To create the cells, the ICFO team used a low temperature hot-injection synthetic procedure. The first stage involved dispersing the nanocrystals into organic solvents, which the researchers claim can remain stable for months with no performance loss to the end product. The nanocrystals were then deposited onto a thin film of ZnO and ITO, to a thickness of approximately 35nm.

“The chemical synthesis of the nanocrystals allows exquisite control of their properties through engineering at the nanoscale and enables their dissolution in colloidal solutions,” said research co-lead Dr Maria Bernechea.

“The material is synthesised at very low temperatures (100ºC), an order of magnitude lower than the ones required for silicon based solar cells.”

According to the researchers, the cells have already achieved an efficiency of 6.3 per cent, similar to high-performance thin film cells when they were in early development. The team is working towards achieving efficiency rates higher than 12 per cent, which along with the lower processing costs would make the technology commercially viable.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...