A major programme to develop and commercialise small modular reactor (SMR) technology is about to begin, with the Sheffield-based Nuclear AMRC confirming that it is to join with Rolls-Royce, AMEC Foster Wheeler, Nuvia and Arup to bring a design proposed by Rolls-Royce to the market in the UK.

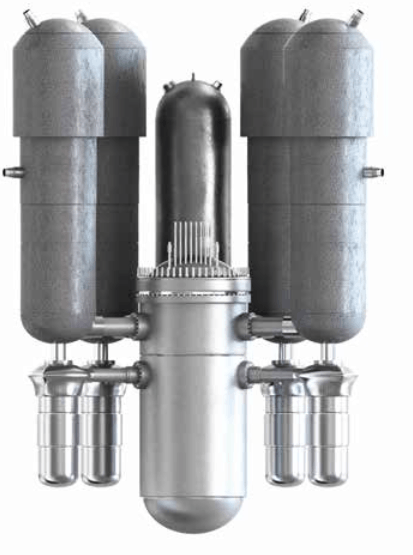

Last year, Rolls-Royce announced that it is proposing to develop a modular reactor capable of producing 220-440MWe depending on its configuration, designed specifically to be built and commissioned in factories, with a reactor module some 16 m high and 4 m in diameter – small enough to be transported on a truck, train or barge. Although it has made public no technical details of the reactor design, its publicity material identifies UK facilities involved in the project that are mostly part of its submarine operations, making it likely that the submarine reactor is the basis of the technology.

Because of its links to the Royal Navy submarine programme, Rolls-Royce is one of the only companies in the world to both build and operate nuclear reactors: it also operates its test reactor near Thurso in Scotland (near to the Dounreay nuclear complex).

Since the 1950s, Rolls-Royce has designed reactors for seven classes of submarine and two land-based prototype reactors. It is now on its third generation of reactor design, and led the development of the first integral reactor in the late 1980s (integral reactors have a reactor core, pressuriser, reactor coolant pumps and steam generators contained within a single pressure vessel, and were the first type of reactor to be designed as 'passively safe' systems that did not require power to be shut down).

According to Rolls-Royce, a UK SMR design could boost the British economy by up to a £100billion between 2030 and 2050, depending on how much of the supply chain is British. The National Nuclear Laboratory produced a report in 2014 that concluded the potential global market for SMRs would be 65 – 85GWe by 2035, with about 75GWe in the UK alone; there is an estimated potential for 40,000 high-value UK jobs and intellectual property.

Last year, the Nuclear AMRC issued a report stating that the UK had the necessary skills and advanced manufacturing capabilities to develop SMR technology; although a notable gap in UK capability is in steam turbine manufacture, where Rolls-Royce has stated that it is looking for an overseas partner (China holds a majority share in worldwide steam turbine manufacturing, with other manufacturers under Indian, German, Korean and Japanese ownership).

The first phase of the development project will see the nuclear AMRC carry out desktop studies on potential methods of manufacture for the Rolls-Royce design, and assess the capabilities of the existing UK supply chain to make the components to the required quality.

Manufacturing processes available include robotic machining, single-platform machining, cryogenic cooling, intelligent fixturing, on-machine inspection, advanced joining and near-net shape manufacturing processes such as electron beam welding, diode laser cladding, automated arc welding, bulk additive manufacturing and hot isostatic pressing: many of these are being developed at the nuclear AMRC, where machine tools and fabrication cells have been specified to a size capable of making full-scale prototype components.

In a statement, Rolls-Royce commented: "We share a common belief that a home-grown SMR program can play a key role in strengthening the UK’s energy mix and security, while creating valuable intellectual property, exports and jobs. We are working together to deliver a whole power plant which could be up and running in just over a decade and provide a boost for the UK’s industrial strategy.”

The government has signalled its commitment to developing SMR technology in last year's budget, with the announcement of £30 million funding available for an SMR-enabling R&D programme to develop skills capacity and advanced manufacturing capability. US company NuScale last year announced that it was to collaborate with UK firms to develop its own SMR technology.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...