When soft materials are used as compressive sensors their elasticity and pliability makes their performance less reliable, a phenomenon known as hysteresis. According to the research team, led by Assistant Professor Benjamin Tee from the NUS Institute for Health Innovation and Technology, the highly sensitive new material (named Tactile Resistive Annularly Cracked E-Skin, or TRACE) has an almost hysteresis-free performance, enabling significantly improved accuracy.

Jellyfish inspire creation of water-resistant electronic skin

ACES to give robots human-like sense of touch

“The TRACE sensor could potentially be used in robotics to perceive surface texture or in wearable health technology devices, for example to measure blood flow in superficial arteries for health monitoring applications,” said Asst. Prof Tee.

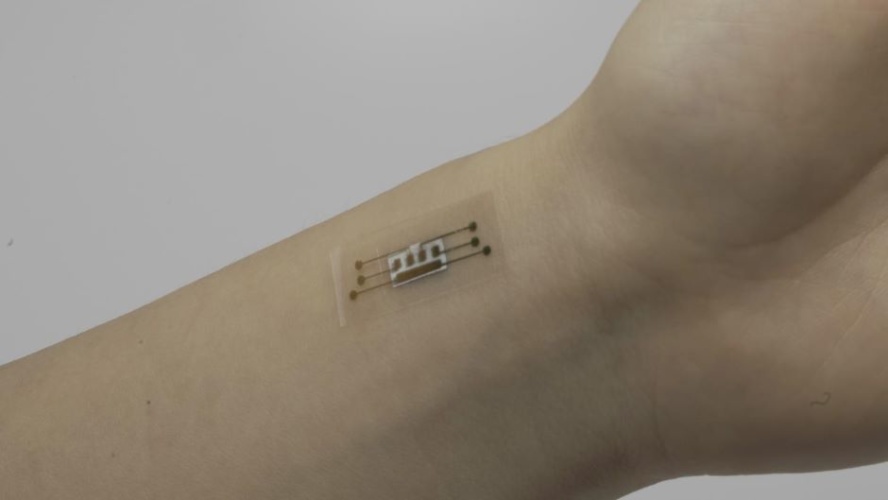

This breakthrough development involved a process to crack thin metal films into desirable ring-shaped patterns on a flexible material called polydimethylsiloxane (PDMS). The team integrated this metal/PDMS film with electrodes and substrates for a piezoresistive sensor and characterised its performance. After conducting repeated mechanical testing, they verified that their design innovation improved sensor performance. Their results are published in the Proceedings of the National Academy of Sciences.

The team now hope to further improve the conformability of their material for different wearable applications, and to develop artificial intelligence (AI) applications based on the sensors.

“Our long-term goal is to predict cardiovascular health in the form of a tiny smart patch that is placed on human skin,” Asst. Prof Tee explains. “This TRACE sensor is a step forward towards that reality because the data it can capture for pulse velocities is more accurate and can also be equipped with machine learning algorithms to predict surface textures more accurately.”

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.