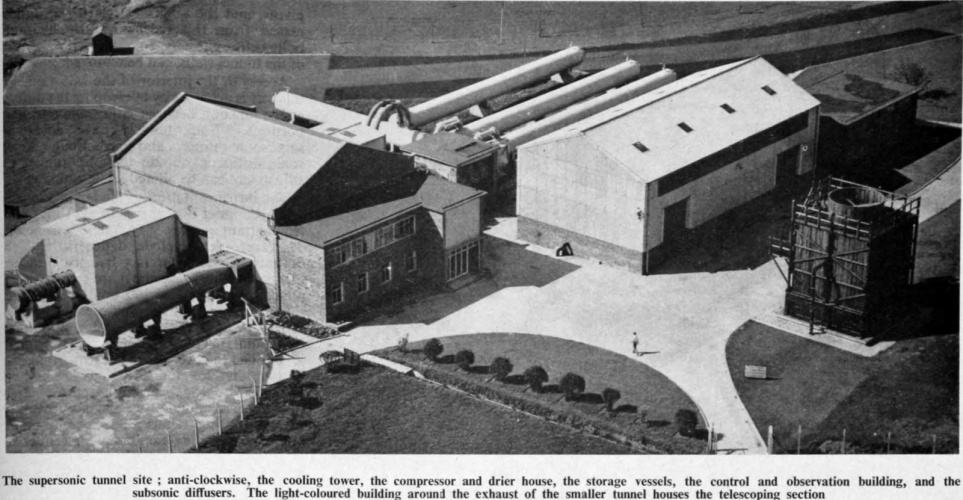

With computing ability advancing rapidly, the 1960s saw some key advances in the application of wind tunnel testing. And in October 1960, The Engineer reported on the opening of two new high speed wind tunnels at the Warton Aerodrome, near Preston.

The facility, which was owned and operated by English Electric, was already home to four other wind tunnels but the two new tunnels introduced a valuable new capability for aircraft and weapons development.

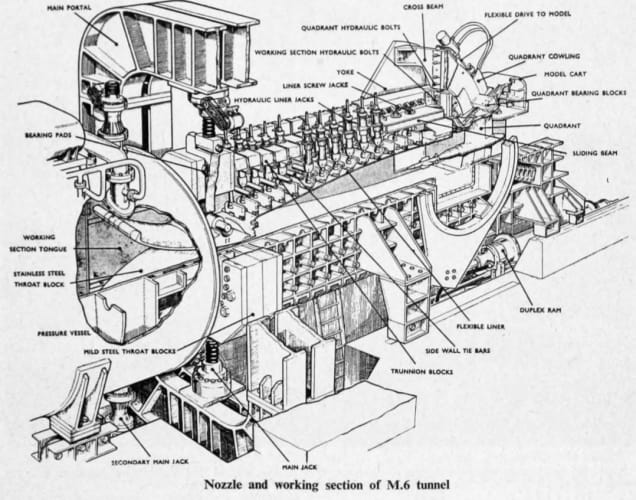

With a speed range from Mach 0·4 to 4·0 and a working section 4ft square, the larger of the two tunnels – M4 - was intended mainly for aircraft development. The smaller tunnel – which had have a speed range of Mach 1·5 to 6·0, and a working section 18in square was described as a guided weapons tunnel.

Because of its wide working speed range, the design of the control system for the larger tunnel proved particularly challenging wrote The Engineer. ’The characteristics of the control valve ….called for a two-stage device in which the first stage opened to an extent inversely proportional to the upstream pressure the constant of proportionality being varied with the desired density and the second stage responded to errors in the selected pressure drop along the tunnel. The article explained that the smaller tunnel had separate shut-off and control valves developed by US firm Compudyne Corporation.

Given the vast computing power available to today’s engineers, the article’s description of how the system’s data was recorded and analysed is perhaps particularly notable. ‘The instrumentation of the larger tunnel is a conventional digital system with all inputs from strain gauges,’ wrote The Engineer. ‘The nine one-second chart recorders include digitisers, and the outputs of the latter are transferred to punched cards up to 100 times per minute.’

The smaller tunnel had a higher speed recording system. ‘Eight quantities, including the balance measurements if being observed, are continuously presented by d.c. amplifiers. At intervals separated by one-eightieth second, sampling amplifiers store these eight values and present them in sequence to a Packard Bell ” Multiverter ” which converts them from analogue to digital form and transfers them in binary code to a high-speed store of magnetic tape. Subsequently the tape record is transferred to punched cards, which, with those from the other tunnel, are processed by a ” Deuce ” computer..’

Amongst other projects, the tunnels, which had been developed and installed at a cost of £750,000 were used in projects as the TSR-2 (Tactical Strike and Reconnaissance aircraft) and the “Blue Water” surface to surface missile.

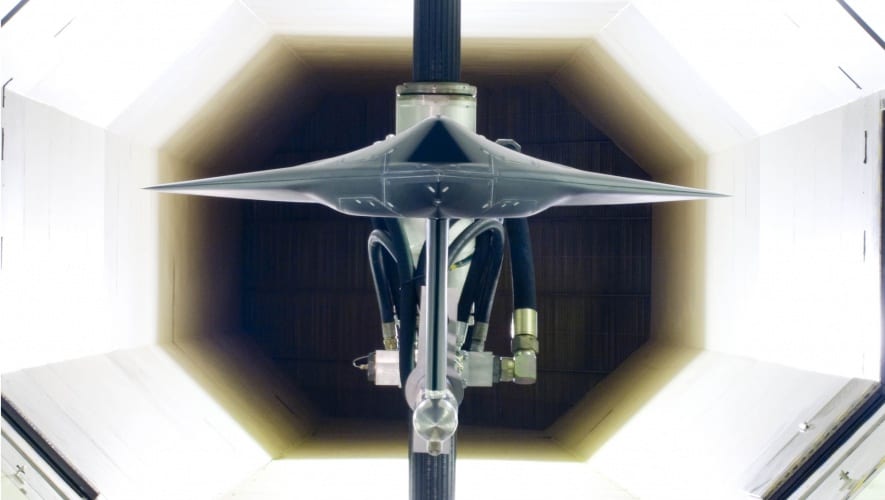

Today, the facility is owned and operated by BAE Systems, and it continues to play a major role in the development of aircraft and weapons systems. It has been used by engineers working on the Tornado, and the Eurofighter Typhoon as well as host of UAV (Unmanned aerial vehicle) projects. The tunnels were even used by the British Bobsleigh team, who, ahead of the 2014 winter Olympics, used them to simulate full racing conditions and examine how different sled set ups and crew positions affect wind resistance.

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?