Aluminium is one of several promising alternatives to lithium-ion battery technology. While not yet capable of the same energy density, aluminium is an abundant resource that is already deeply embedded in industrial cycles and is potentially much more environmentally friendly than lithium.

FutureCat plugs into next generation of lithium-ion batteries

Faraday funding puts battery research on full-charge

Until now, aluminium batteries have used graphite cathodes, but the energy density of graphite has proved too low for the cells to be useful. The new cathode, described in Energy Storage Materials, could lay the path for low-cost, greener batteries that might one day compete with their lithium-ion counterparts.

"The material costs and environmental impacts that we envisage from our new concept are much lower than what we see today, making them feasible for large scale usage, such as solar cell parks, or storage of wind energy, for example," said research lead Patrik Johansson, Professor at the Department of Physics at Sweden’s Chalmers University of Technology.

"Additionally, our new battery concept has twice the energy density compared with the aluminium batteries that are 'state of the art' today."

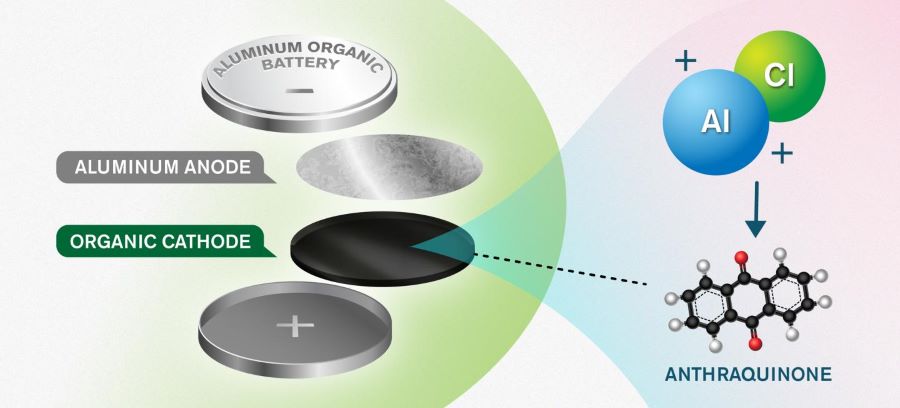

The new concept, created by Johansson in collaboration with researchers at Slovenia’s National Institute of Chemistry, replaces the graphite cathode with one made of anthraquinone, which is a carbon-based molecule. This nanostructured material enables storage of positive charge-carriers from the electrolyte, which facilitates a higher energy density in the battery.

"Because the new cathode material makes it possible to use a more appropriate charge-carrier, the batteries can make better usage of aluminium's potential,” said Chalmers researcher Niklas Lindahl.

“Now, we are continuing the work by looking for an even better electrolyte. The current version contains chlorine - we want to get rid of that.”

While Johansson hopes that the aluminium concept could eventually replace lithium-ion, in the short term the technology could be complimentary, ensuring lithium was only used in batteries where the energy requirements demanded it.

“So far, aluminium batteries are only half as energy dense as lithium-ion batteries, but our long-term goal is to achieve the same energy density,” he said.

“There remains work to do with the electrolyte, and with developing better charging mechanisms, but aluminium is in principle a significantly better charge carrier than lithium, since it is multivalent - which means every ion 'compensates' for several electrons.”

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?