The findings from North Carolina State University, MIT and the University of Michigan are said to represent a fundamental advance in the understanding of suspensions in flow.

“We heard about problems companies were having with pumping suspensions and became curious about what was causing these problems,” said Lilian Hsiao, an assistant professor of chemical and biomolecular engineering at NC State and lead author of a paper on the work. “Given the ubiquity of these types of fluids in the industry, we were surprised that no one had systematically looked at the role of surface roughness before. That turns out to be a really important factor in how these particle-laden fluids flow.”

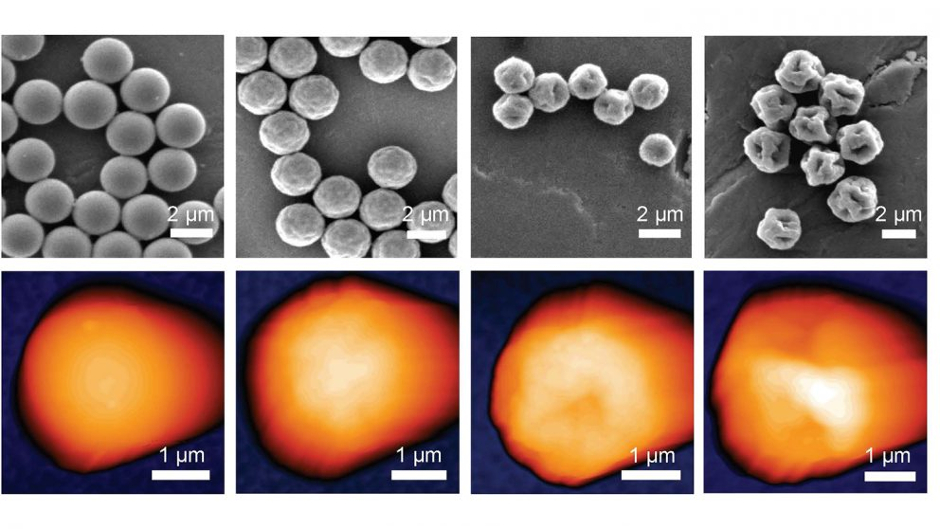

Using a combination of simulations and laboratory experiments, the researchers found that friction was slowing down the suspensions. According to NC State, the friction becomes significant when enough particles suspended in the liquid collide with each other; the rougher the surface of the particles, the more friction they generate when they come into contact.

“It takes energy to pump a liquid suspension through a pipe or tube, and the friction created by interaction between particles dissipates a lot of that energy,” Hsiao said. “This dissipation slows down the movement of the suspension or, if the particles are very rough, can even stop it completely.”

This insight gives industries two options: they can reduce friction by engineering the particles to have smoother surfaces, or they can increase the amount of energy used to move the suspension through the pipe.

The researchers also found that adding energy to a suspension that contains rough particles can also cause the suspension to expand. This is because rough particles take up more space than smooth ones when tumbling in suspension. The end result is that putting more shear stress into the system can cause catastrophic clogging if the suspension expands too much.

“This is a fundamental advance in our understanding of the physics of suspensions in flow, and should help engineers and scientists address the manufacturing challenges that caught our attention in the first place,” Hsiao said. “We’re now looking at ways to use the principles we discovered here to make the friction work in our favour.”

The paper, “Rheological state diagrams for rough colloids in shear flow,” is published in the journal Physical Review Letters. The paper was co-authored by Safa Jamali of MIT, and Emmanouil Glynos, Peter Green, Ronald Larson and Michael Solomon of Michigan.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...