MIT Associate Professor Juejun Hu said that there is interest in the possibility of optical technologies that can stretch and bend, especially for applications such as skin-mounted monitoring devices that could directly sense optical signals. Such devices might simultaneously detect heart rate, blood oxygen levels, and even blood pressure.

The findings, which involve the use of chalcogenide, a specialised form of glass, are described in a paper by Hu and others at MIT, the University of Central Florida, and universities in China and France. The paper is slated for publication in Light: Science and Applications.

Photonic devices process light beams directly using systems of LEDs, lenses, and mirrors fabricated with the same kinds of processes used to manufacture electronic microchips. Using light beams rather than a flow of electrons can have advantages for many applications; if the original data is light-based, for example, optical processing avoids the need for a conversion process.

In a statement, Hu said many photonics devices are fabricated from rigid materials on rigid substrates and have an “inherent mismatch” for applications that “should be soft like human skin.” However, most soft materials, including most polymers, have a low refractive index, which leads to a poor ability to confine a light beam.

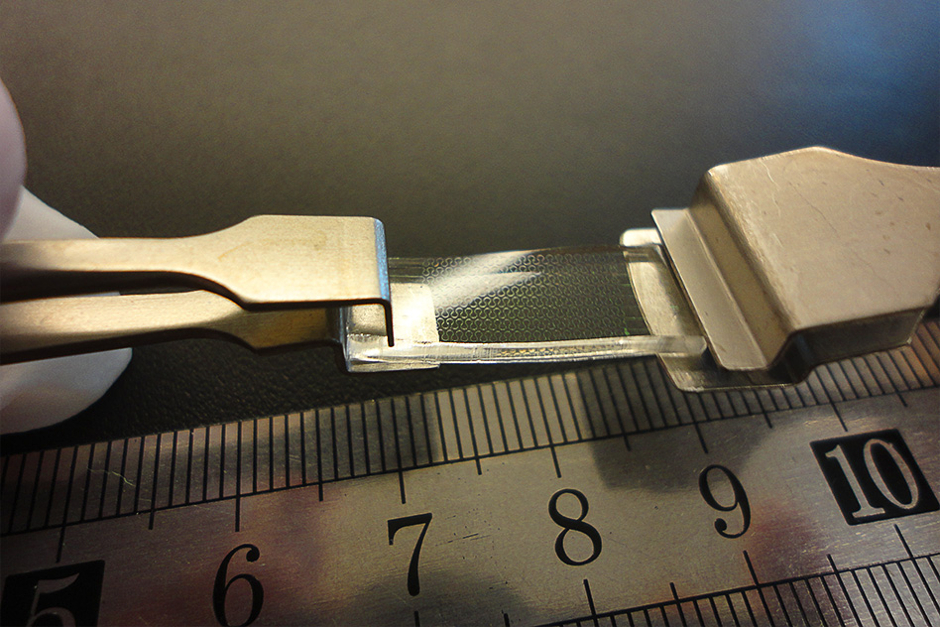

Instead of using such flexible materials, Hu and his team formed the stiff material - a thin layer of chalcogenide - into a spring-like coil. The architecture of this glass coil allows it to stretch and bend freely while maintaining its desirable optical properties.

“You end up with something as flexible as rubber, that can bend and stretch, and still has a high refractive index and is very transparent,” Hu said. Tests have shown that such spring-like configurations, made directly on a polymer substrate, can undergo thousands of stretching cycles with no detectable degradation in their optical performance.

The team reportedly produced a variety of photonic components, interconnected by the flexible, spring-like waveguides, all in an epoxy resin matrix, which was made stiffer near the optical components and more flexible around the waveguides.

Other kinds of stretchable photonics have been made by embedding nanorods of a stiffer material in a polymer base, but those require extra manufacturing steps and are not compatible with existing photonic systems, Hu said.

Such flexible, stretchable photonic circuits could also be useful for applications where the devices need to conform to the uneven surfaces of another material, such as in strain gauges. Optics technology is very sensitive to strain, according to Hu, and could detect deformations of less than one-hundredth of one per cent.

The research is still in early stages and Hu’s team has so far demonstrated single devices.

“For it to be useful, we have to demonstrate all the components integrated on a single device,” he said. Work is ongoing to develop the technology to that point so that it could be commercially applied, which Hu said could take another two to three years.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...