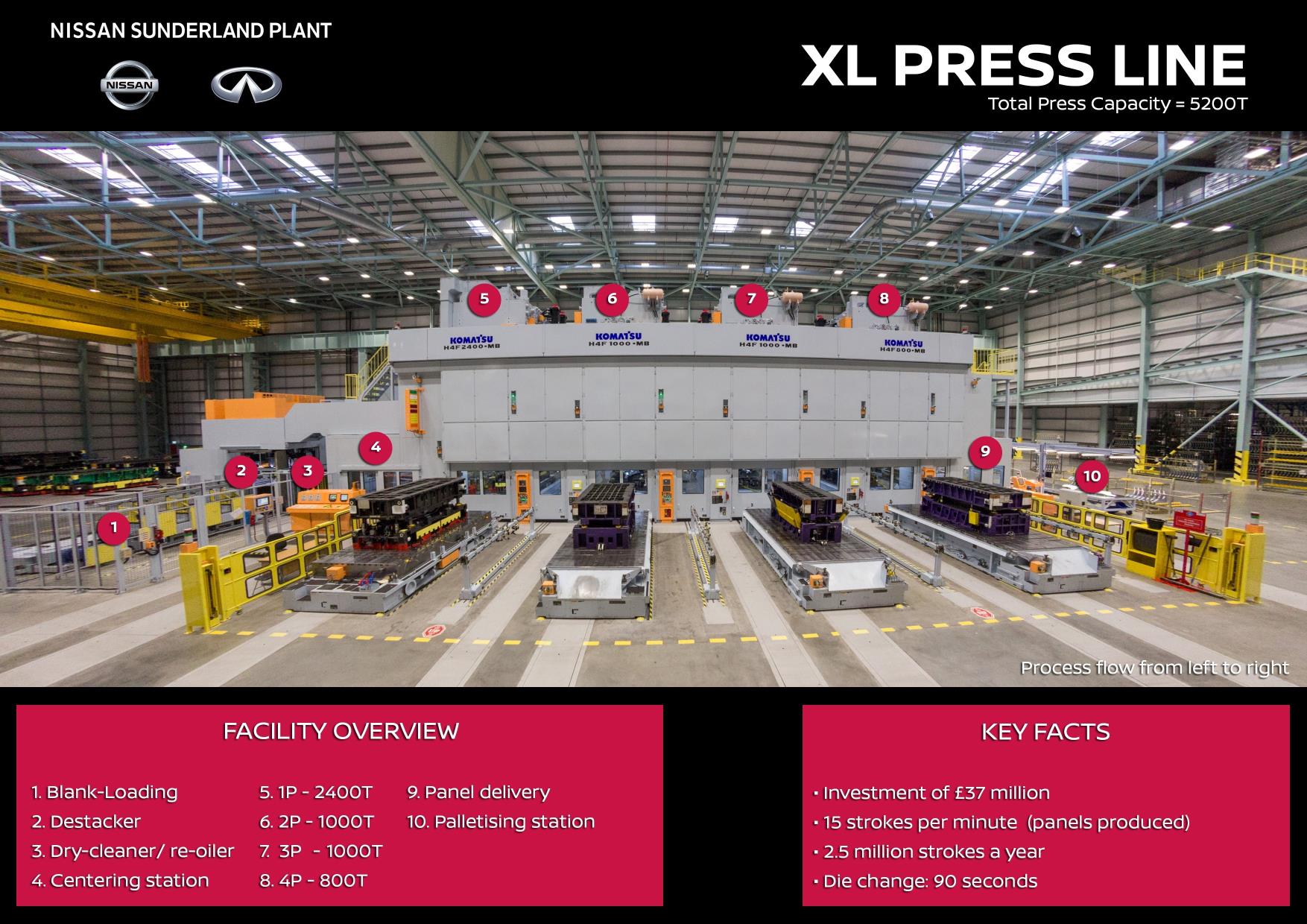

Nissan will be able to stamp 2.5 million panels a year at its plant in Sunderland after starting production with its new extra-large press.

The new press line and panel storage area required a building extension totalling 6,780m², taking the total built up space on site above 362,000m².

Nissan's divisional vice president, European Manufacturing, Kevin Fitzpatrick, said: “The new press is a fantastic piece of cutting edge technology which sets up the next generation of production at Nissan Sunderland Plant.

“The quality of the build and the efficiency of the installation are a real credit to the dedication, talent and sheer hard work of our team at the plant.

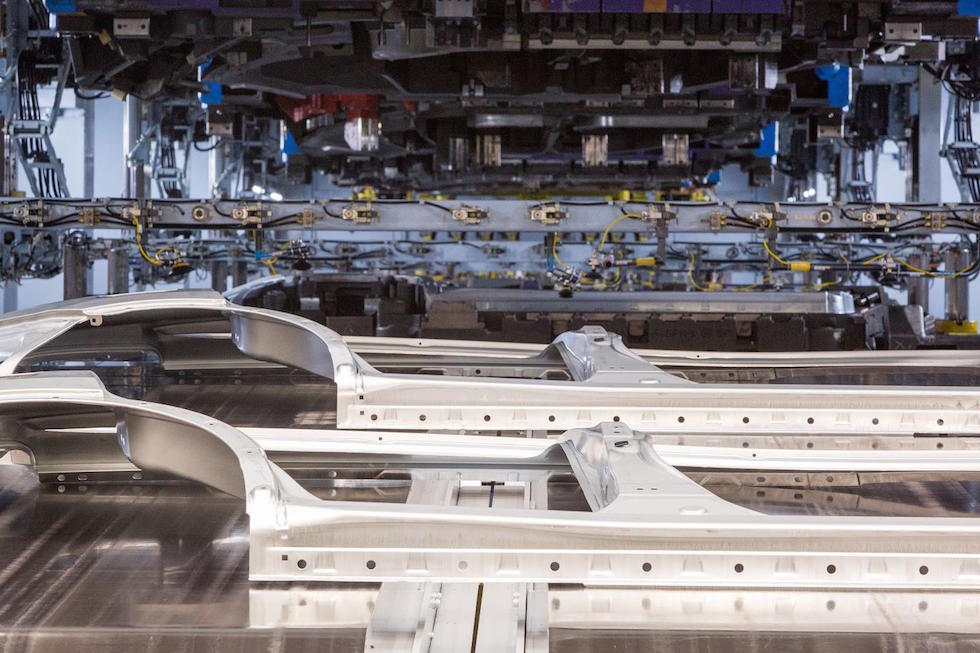

More than 10m in height, with foundations deeper than 6.5m, the £37m facility will press body sides and other panels for vehicles built in Sunderland, including the Qashqai and Juke, Nissan LEAF, plus Infiniti models, Q30 and QX30.

The new XL press, the first of its type in the Renault-Nissan Alliance, will be the biggest at Sunderland and joins the existing seven press lines.

The new press, which stamps panels with force in excess of 5,200 tonnes, forms part of the £650m on-going investment in new facilities and future models in Sunderland, which has taken the total capital investment by Nissan in the plant since it opened in 1986 to over £4bn.

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...