Using the heat of the body to power small electronic devices has been a goal of developers for some time, especially as heart rate or respiration monitors consume only small amounts of power. But thermoelectric devices, which use differences in temperature to generate a flow of current, have always been too large and inflexible, and required materials too toxic to be useful for this. A team at Georgia Tech has now devised a way to make generator circuits that can be printed onto flexible materials and cut to size according to how much power is needed.

The circuits generate power through dots made up of layers of semiconducting polymers. Two types of polymer are used; n-type (which has excess electrons that can move along and between polymer chains), and p-type (which is deficient in electrons, leading to mobile positively-charged ‘holes’ that can move similarly). Printing these dots with an inkjet printer allows them to be closely spaced, maximising the heat collected per unit area and the resulting power output of the device.

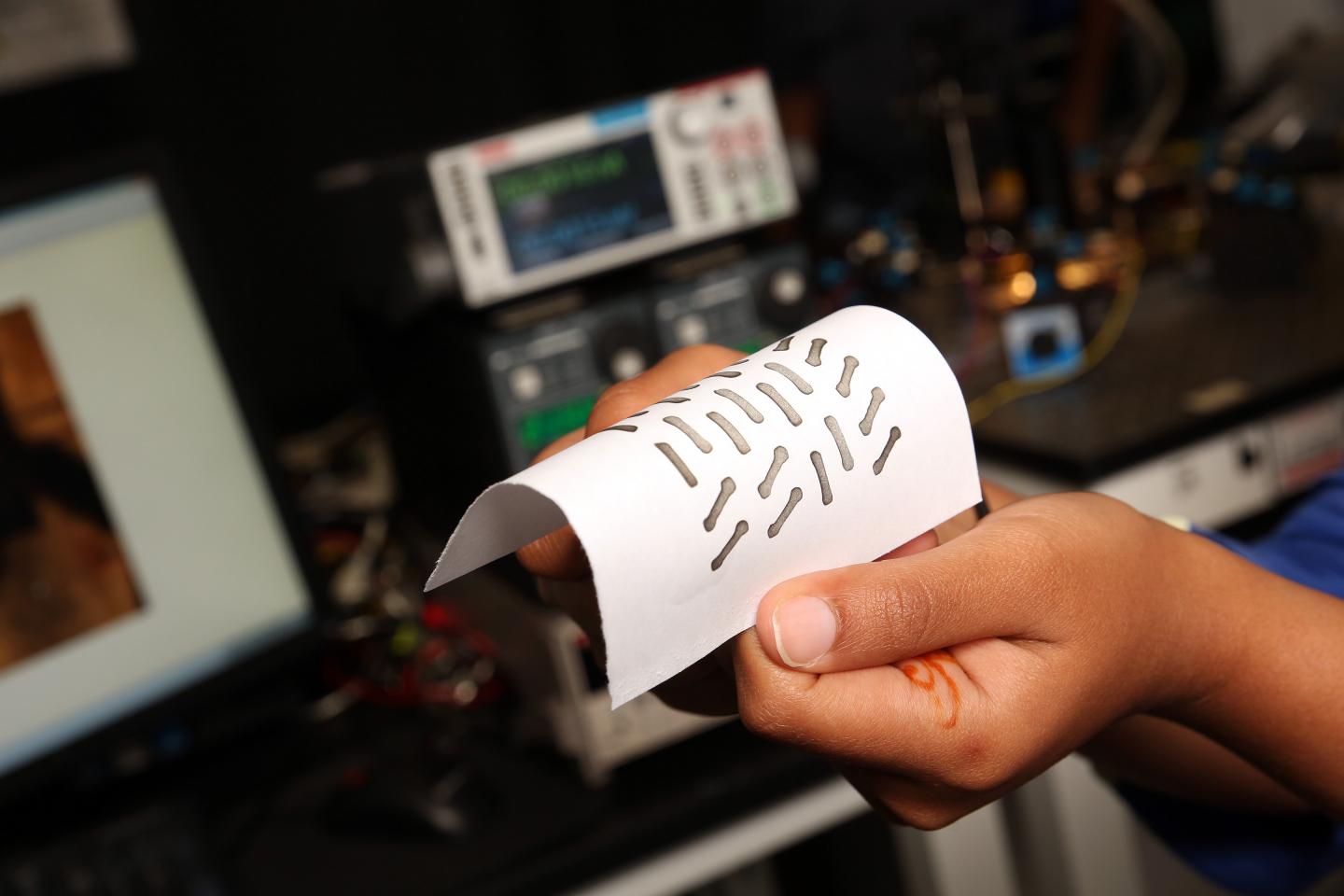

But key to the innovation is the wiring pattern used to connect these dots, which is based on a fractal space-filling curve called the Hilbert Figure. This has two advantages: it helps the circuit bend to keep the maximum amount of its area in contact with the skin, giving a more uniform temperature across the device, and it allows the device to be cut along the boundaries of symmetrical areas of the pattern, to provide the precise voltage and power a device would need. This removes the need for power converters that would reduce the efficiency of the system. The team expects the circuits to generate power in the microwatt to milliwatt scale.

In the Journal of Applied Physics, the Georgia team describe how the circuits can be printed onto paper or fabric. "We want to integrate our device into the commercial textiles that people wear every day," said PhD student Akanksha Menon, who worked on the project. "People would feel comfortable wearing these fabrics, but they would be able to power something with just the heat from their bodies."

Although they are using commercial p-type polymers, they hope to work with chemists to develop n-type polymers that will allow devices to generate power from temperature differences as low as 5°degC, which is typical of indoor conditions. “One future benefit of this class of polymer material is the potential for a low-cost and abundant thermoelectric material that would have an inherently low thermal conductivity," said Shannon Yee, who directs the lab where the research took place.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...