The possibility of growing electronic devices from bacteria seeded with metal nanoparticles has been raised by researchers from Duke University in North Carolina. The team has demonstrated that bacteria can be programmed to self-organise into a form that the cells themselves can transform into components of a working sensor.

The research mimics an action commonly seen in nature, where a living system combines inorganic materials and organic materials to make new materials with exceptional properties. Mollusc shells, for example, combine the mineral calcium carbonate with small amounts of proteins that greatly increase the mineral’s strength. Bone is a similar composite of organic collagen and inorganic minerals made up of various salts

"Nature is a master of fabricating structured materials consisting of living and non-living components," said Lingchong You, who led the research. "But it is extraordinarily difficult to program nature to create self-organised patterns. This work, however, is a proof-of-principle that it is not impossible."

In a paper in Nature Biotechnology, You’s team describes how they achieved their goal by inserting a gene circuit into the DNA of a strain of the common bacterium E coli. This circuit is a sequence of instructions that makes the cell build proteins that alter its behaviour. Seeding a porous membrane material with the modified bacteria, they added a nutrient solution to encourage the bacteria to grow. The gene circuit then forced the cells to make, or express, a protein called T7 RNA polymerase (T7RNAP), which activates in own expression in a feedback loop, and also triggers the production of a small molecule called AHL that diffuses into the cell’s environment and acts as a messenger.

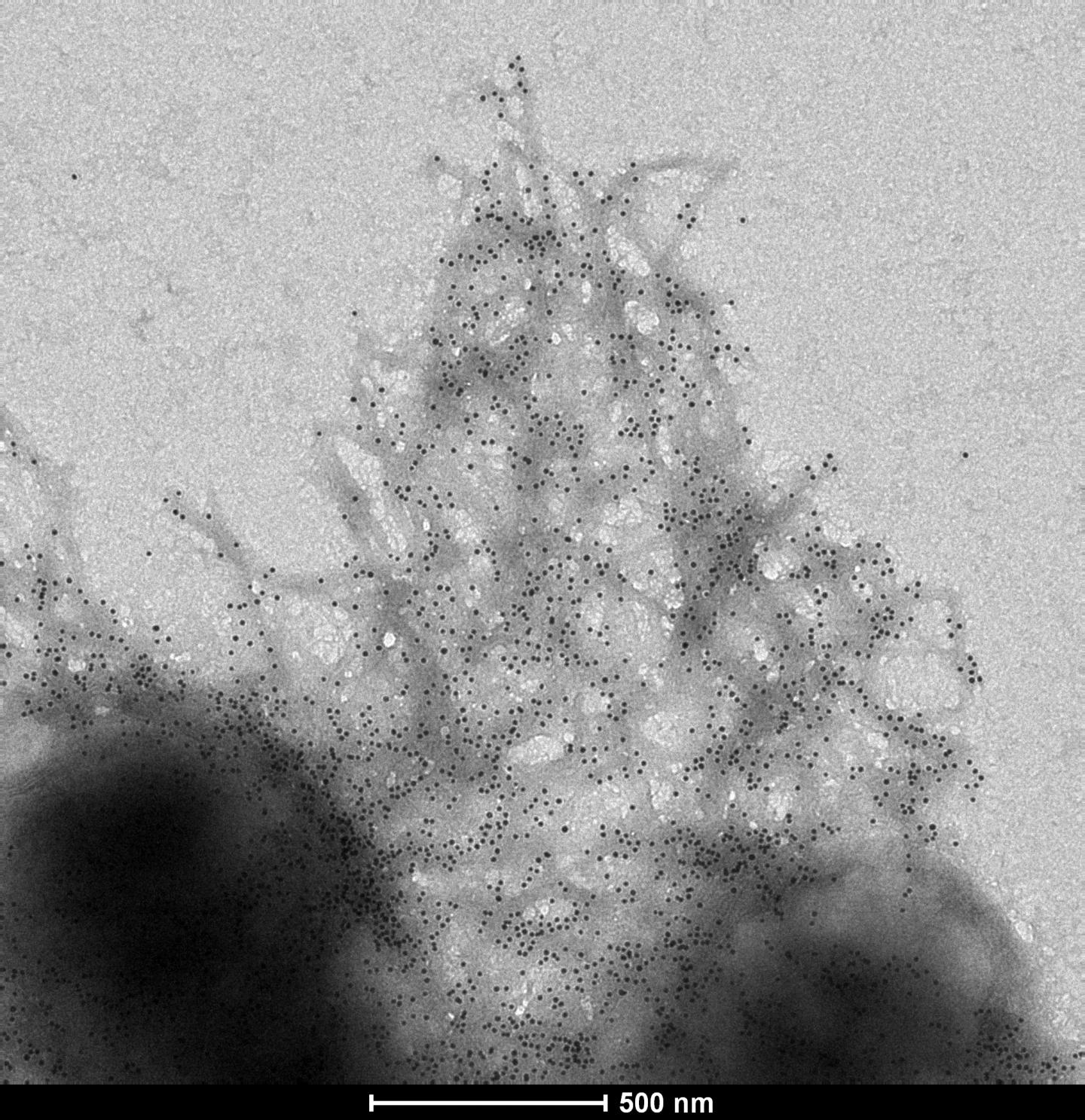

The cells grow outwards on the membrane, forming a hollow dome, and when the AHL reaches a specific concentration it triggers a change in behaviour, activating the expression of two more proteins called T7 lysosome and curli. The former switches off the production of T7RNAP, while the latter, which builds up on the outer surface of the dome, acts as a kind of biological Velcro, grabbing onto inorganic material in the environment.

Once the domes have stopped growing — controlled by the amount of nutrient supplied by the researchers — they added a suspension of gold nanoparticles, which were grabbed by the curli proteins to form flexible shell over the dome. The team grew two identical gold dome-covered membranes and sandwiched them together, gold sides inward, so that domes were touching. They then connected each side in a circuit with a battery and an LED. Pressing onto one side of the sheet compressed the domes, resulting in a reduction in electrical resistance which caused current to flow and light the LED, with its brightness corresponding to how much pressure was applied.

Unlike previous attempts to use bacteria to build devices, the cells build a three- rather than two-dimensional structure and there is no need to control where the cells grow. "We're demonstrating one way of fabricating a 3D structure based entirely on the principal of self-organisation," said team member Stefan Zauscher. "That 3D structure is then used as a scaffold to generate a device with well-defined physical properties. This approach is inspired by nature, and because nature doesn't do this on its own, we've manipulated nature to do it for us." You added that "Fundamentally, it is no different from programming a cell to grow an entire tree."

The size and shape of the dome structure can be altered by changing the membrane the cells grow on; for example, changing its porosity controls how much nutrient can reach the bacteria. This approach could be attractive because tweaking growth instructions to create different shapes and patterns could theoretically be much cheaper and faster than casting the new dies or moulds needed for traditional manufacturing. "In this experiment we're primarily focused on the pressure sensors, but the number of directions this could be taken in is vast," said Will Cao, a postdoctoral associate in You's laboratory and first author of the paper. "We could use biologically responsive materials to create living circuits. Or if we could keep the bacteria alive, you could imagine making materials that could heal themselves and respond to environmental changes." You commented that the team would like to make much more complex patterns. "Bacteria can create complex branching patterns, we just don't know how to make them do that ourselves -- yet."

See the pressure switch working:

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...