It is hoped the associated performance increases will drive commercialisation of this type of energy generation, which is now at the pilot stage.

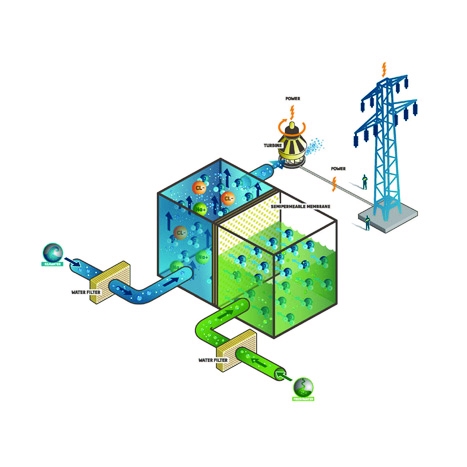

Osmotic power exploits topographical areas where seawater and fresh water meet. By placing a separating membrane between the two fluids, fresh water permeates through the membrane to the seawater side, resulting in an increase in pressure on this side, which is used to drive a turbine and generate electrical energy.

To achieve the required energy efficiency, as much as five million square metres of membrane will be needed to operate an osmotic generating plant with a production output of 25MW. This will be achieved by packing membranes in special modules, with each cubic metre of module containing up to a thousand square metres of membrane.

‘The most challenging part is still to get efficient enough membranes — but we are close now,’ Edvard Sivertsen, a project manager at SINTEF Building and Infrastructure, told The Engineer.

‘The membrane is basically two layers: there’s a dense, very thin layer giving the first two properties of water permeability and salt retention; and the second layer, giving the structural parameter, which is a function of thickness, porosity and tortuosity.’

According to Sivertsen, the second challenging aspect of the project will be producing membranes robust enough to deal with naturally occurring organic contaminant compounds that can foul the membrane and negatively affect performance.

The latest two-year project between SINTEF, Scandinavia’s largest independent research organisation, and Statkraft will research and develop new membrane modules in isolation at purpose-built laboratories then test them at one of Statkraft’s pilot osmotic plants currently in operation.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...