Originally founded in the early 1970s to carry out high precision CNC machining for the motorsport sector, the CRP group has evolved over the past four decades to become one of Europe’s leading specialists in new production technologies, such as additive manufacturing.

Headquartered in Modena, Italy’s renowned motor valley, the Group is made up of specialised companies: CRP Meccanica, CRP Service, CRP Technology, CRP USA.

With an emphasis on customisation, high-end technologies, and a broad range of applications the group has strong relationships with companies and entrepreneurs in the automotive, motorsport, design, aerospace, Unmanned Aerial Vehicles (UAVs), marine and entertainment sectors.

CRP was one of the first firms to import additive manufacturing technology to Europe and Italy, and in 1996 created its own in-house 3D printing department, equipped with Selective Laser Sintering technology, and backed up by a specialist R&D department.

The group’s Windform family of high performance laser sintering materials, has been in use across a range of sectors for more than 20 years, and has been deployed in applications as diverse as as outgas tests for use in space; patch testing for the medical sector; and fashion and design.

The companies making up the current business group are now able to offer the market and their clients a consolidated alternative to traditional manufacturing methods for small series, and for the production of functional prototypes and end-use components.

CRP Group provides expertise in Additive Manufacturing and 3D printing with Windform materials; development, production and sales of laser sintering and 3D printing materials; High-precision CNC machining; Direct Metal Laser Sintering (DMLS); Electron Beam Melting (EBM).

CRP Meccanica provides high precision CNC machining for the motorsports, automotive, aerospace, and marine sectors and offers services to companies that require a high level of customisation and accuracy. It also offers a wide range of processed materials and high-tech Direct Metal Laser Sintering/Selective Laser Melting machines.

CRP Technology offers parts production for short- and limited-number production runs, and prototyping services with advanced 3D printing and additive manufacturing solutions. As a materials provider, CRP Technology develops, manufactures and markets its proprietary Windform laser sintering material.

CRP Technology is also synonymous with custom production thanks to its experience in creating short-run productions and pre-series productions, in a process that moves from a CAD 3D file to the finished component in just one step.

The department of additive manufacturing and 3D printing is one of the most important in terms of state-of-the-art technologies and services supplied, delivering maximum quality within the shortest possible time frame, both within Italy and throughout the worldwide market.

CRP USA is strategically located in the heart of NASCAR country in North Carolina, and specialises in additive manufacturing and 3D printing applications.

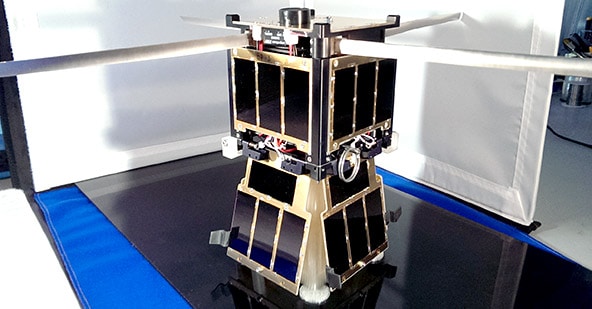

CRP USA manufactures on-car and wind tunnel components for racing teams. It has taken this expertise to new heights to produce parts for the space (Satellite and CubeSat structures), entertainment and automotive industries using Windform materials and additive manufacturing technology.

F1 means obsessive attention to details that quite often make the difference. There is continuous research for the next technology innovation to get that competitive advantage even of few hundredths of a second: the F1 background has been precious for the development of the first electric racebike, the eCRP, from which the company started the electric program. It recently has given rise to Energica Motor Company, the sustainable subsidiary of CRP Group and the first Italian manufacturer of supersport electric motorcycles. Energica benefits in countless and immeasurable ways from the close relationship and consultation with parent company CRP Group, that keeps Energica at the forefront of state-of-the-art technology and ready for future technology innovation.

Applications

CRP Group has reduced the gap towards established production and alternative technologies and it is involved as technological partner in several projects spanning from motorsports and automotive to aerospace.

Space: Windform 3D Printing materials launch into Orbit on KySat-2

Motorsport: The electrical enclosure for Nascar racecars

Automotive: Kepler Motors Brings Titanium Uprights to the Roadway with Additive Manufacturing and CRP Groups’ Expertise

UAVs: The construction of the first “leisure drone” body in Windform

Content supplied by CRP Group and edited by The Engineer

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...