Users of prosthetic hands often find one common movement particularly difficult or even impossible: pronation and supination. These are the movements enabled through rotation of the wrist, such as turning the hand from palm down to palm up on a flat surface. For able-bodied people, such movements are extremely common, useful tasks such as turning a door handle or using tools.

But such movements are very difficult to replicate using conventional prosthetics. Those which attach to the remaining stump using a socket tend to lock the forearm bones – the radius and ulna – in one position, rendering rotation impossible. Even motorised prosthetics have problems.

"A person with forearm amputation can use a motorised wrist rotator controlled by electric signals from the remaining muscles. However, those same signals are also used to control the prosthetic hand," said Max Ortiz Catalan of the Department for Electrical Engineering at Chalmers University of Technology in Sweden. "This results in a very cumbersome and unnatural control scheme, in which patients can only activate either the prosthetic wrist or the hand at one time and have to switch back and forth. Furthermore, patients get no sensory feedback, so they have no sensation of the hand's position or movement."

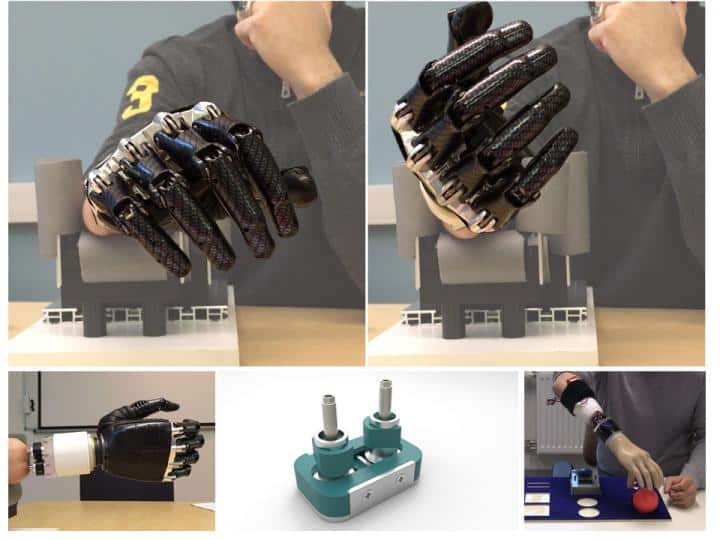

Ortiz Catalan has been addressing the problem, and describes in a paper in the journal IEEE Transactions on Neural Systems and Rehabilitation Engineering a new type of prosthetic implant which enables a realistic pronation and supination movement. This prosthetic implant is attached to the user by osseointegration: that is, the attachment points are surgically implanted directly into the patient's radius and ulna. The implant is then attached to a wrist-like artificial joint that acts as an interface between the surgical implant and a prosthetic hand. This allows the user’s remaining skeletal structure and musculature to be used in the same fashion as those of an able-bodied person, Ortiz Catalan said.

"Depending on the level of amputation, you could still have most of the biological actuators and sensors left for wrist rotation. These allow you to feel, for example, when you are turning a key to start a car. You don't look behind the wheel to see how far to turn - you just feel it. Our new innovation means you don't have to sacrifice this useful movement because of a poor technological solution, such as a socket prosthesis. You can continue to do it in a natural way," said Ortiz Catalan.

Once considered too radical as a realistic option for human prosthetics, osseointegration is now being actively considered by several researchers, as The Engineer reported earlier in the year. At the recent service to mark the UK Year of Engineering at Westminster Abbey, Colonel Deborah Porter, Deputy Commander of the Defence Medical Group, described how the technique is helping soldiers injured on the battlefield.

The prosthetic implant was developed by Swedish-based medical technology company Integrum AB, which was a partner in Ortiz Catalan’s research. The co-authors of his paper, biomedical engineers Irene Boni and Jason Millenaar, have tested the implant and believe it could have life-changing consequences for users. "In tests designed to measure manual dexterity, we have shown that a patient fitted with our artificial joint scored far higher compared to when using conventional socket technology," Millenaar said.

"Our new device offers a much more natural range of movement, minimising the need for compensatory movements of the shoulder or torso, which could dramatically improve the day to day lives of many forearm amputees," says Boni.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...