The team of materials researchers at North Carolina State University have fine-tuned the technique to coat quantum dot nanorods in a day, which is up to 21 times faster than previous methods. In addition to saving time, the advance means the quantum dots are less likely to degrade, thereby preserving their optical properties.

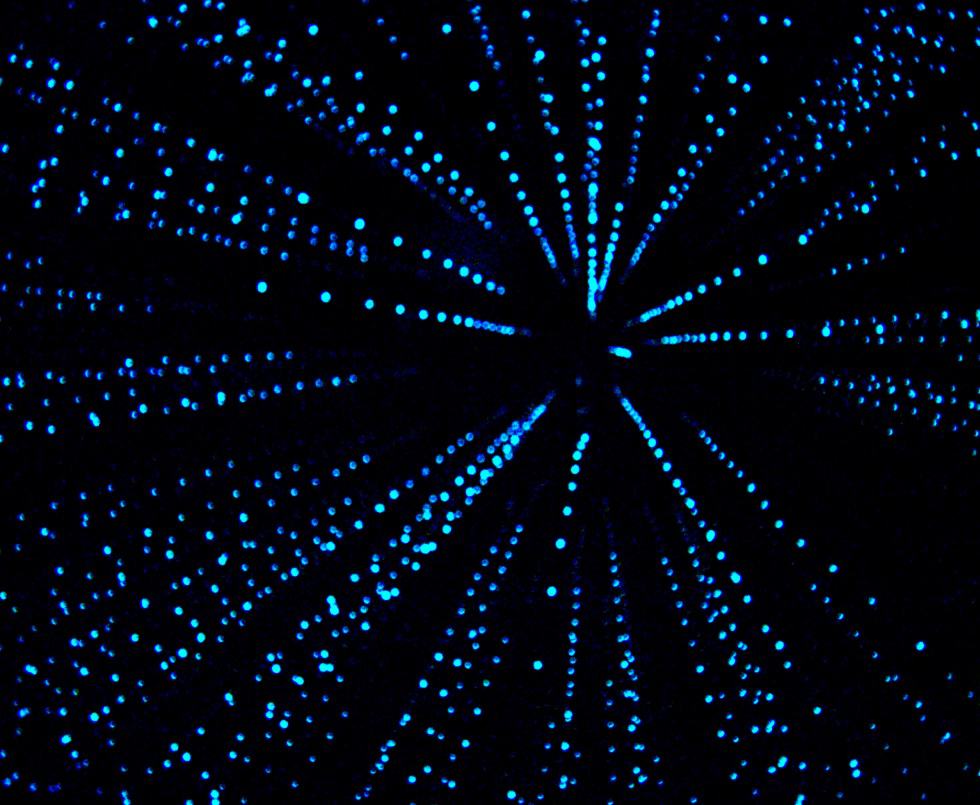

Quantum dots are nanoscale semiconductor materials with energy levels that differ from larger-scale versions of the same material. By controlling the size of the quantum dots, researchers can control the energy levels that give quantum dots novel optical properties. These characteristics make quantum dots promising for applications in optoelectronics and display technologies.

Quantum dots are, however, surrounded by ligands. These organic molecules are sensitive to heat and if they are damaged the optical properties of the quantum dots diminish.

"We wanted to coat the rod-shaped quantum dots with silica to preserve their chemical and optical properties," said Bryan Anderson, a former Ph.D. student at NC State who is lead author of a paper on the work. "However, coating quantum dot nanorods in a precise way poses challenges of its own."

Previous work by other research teams has used water and ammonia in solution to facilitate coating quantum dot nanorods with silica but those techniques did not independently control the amounts of water and ammonia used in the process.

By independently controlling the amounts of water and ammonia used, the NC State researchers were able to match or exceed the precision of silica coatings achieved by previous methods. In addition, the NC State team was able to complete the entire silica-coating process in a day, rather than one-to-three weeks needed through other processes.

"The process time is important, because the longer the process takes, the more likely it is that the quantum dot nanorods being coated will degrade," said Joe Tracy, an associate professor of materials science and engineering at NC State and senior author on the paper. "The time factor may also be important when we think about scaling this process up for manufacturing processes."

The process of applying the silica coating etches the cadmium sulphide surface of the quantum dot nanorods, which shortens the length of the nanorods by as much as four or five nanometres. According to NC State, that shortening is indicative of etching, which reduces the brightness of the light emitted by the quantum dot nanorods.

"We think ammonia may be the culprit," Tracy said. "We have some ideas that we're pursuing, focused on how to substitute another catalyst for ammonia in order to minimize the etching and better preserve the quantum dot nanorod's optical properties."

The paper, Silica Overcoating of CdSe/CdS Core/Shell Quantum Dot Nanorods with Controlled Morphologies, is published in the Chemistry of Materials. The paper was co-authored by Wei-Chen Wu.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...