Zircotec Group has created an R&D facility to accelerate the development of new thermal coatings, heat shields and manufacturing processes.

Under the leadership of Dr Paul Prince, the facility is expected to provide data on the high temperature performance of thermal barrier coatings.

“Unlike academic research, our activities will provide an immediate commercial benefit for our customers by enabling us to select the optimum solutions for their individual applications more quickly,” said Dr Prince. “We can compress the timescale for each new application by using a comprehensive database on material performance to guide the initial selection, reducing the number of design iterations needed to reach the optimum result. The facility will also enable us to develop new solutions and advance our manufacturing processes.”

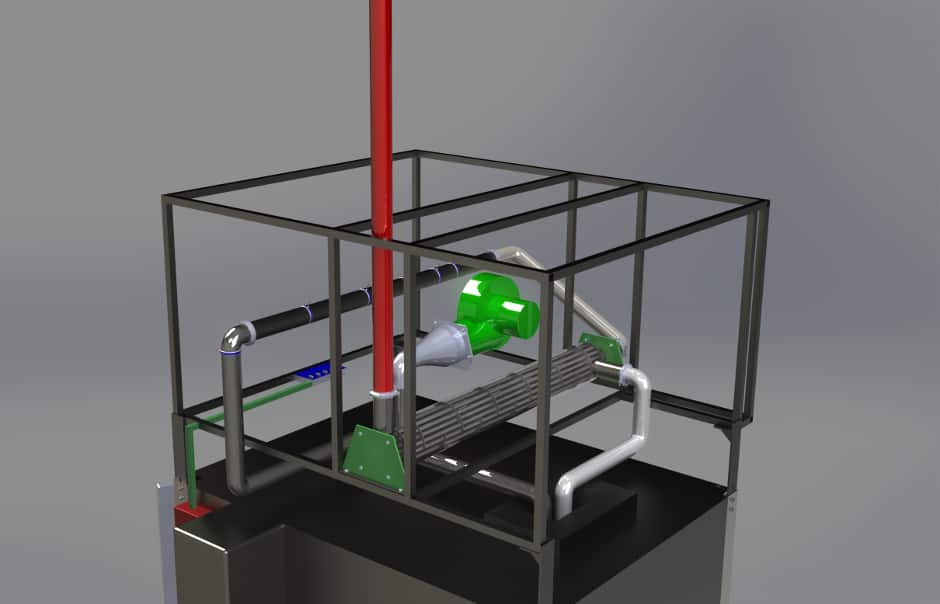

The test rig uses a controlled heat source to evaluate coatings and heat shields at gas temperatures up to 900°C but can also generate useful data at much lower temperatures. Two engineers are currently working with the rig on projects that Zircotec said will result in new products and cost-effective processes to manufacture them.

The coatings and processes developed will be applicable to heat shields, surrounding components and directly onto the heat source itself.

Dr Prince said that Zircotec’s investment has been driven by demand from the automotive industry for solutions to manage higher exhaust line temperatures.

“Pressures to reduce emissions and improve engine efficiency are leading to powertrain strategies that continually increase exhaust temperatures,” he said. “For example, the use of alternative fuels, such as natural gas in place of petrol or diesel, can raise the exhaust temperature by 200°C. Accommodating such a large increase within a packaging space that is often highly constrained requires advanced thermal barrier technology.”

In addition to the high temperature rig, Zircotec is investing in thermal imaging equipment that will provide more comprehensive insights into temperature distributions than can be achieved through conventional instrumentation.

Nanogenerator consumes CO2 to generate electricity

The chemistry seems incredibly complex. When the article came out here in Australia the News report was really funny because they scientist/researcher...