When talking to Ric Parker about the technology he’s overseeing development of at Rolls-Royce, you realise you’re not just discussing the future of one of Britain’s leading engineering companies but that of the entire civil aerospace sector. Since privatisation in 1987, Rolls-Royce has grown to become the world’s second-largest manufacturer of aircraft engines and so its technical direction has a huge impact on the world’s aviation fleet. That includes not just the fuel efficiency, carbon emissions and noise of aircraft but also their fundamental look and design.

Speaking to The Engineer after giving a recent talk on innovation at product development firm Pera Technology, Parker explained that one of the key challenges in developing a new kind of engine — in this case the open-rotor design that some see as the future for civil airliners — is working out where on the aircraft to locate them. ‘If you put them under the wing then you finish up with a very heavy and very long undercarriage,’ he said. ‘If you put them on top of the wing then the aerodynamics get a bit strange. One solution might be to go back to mounting the wing across the top of the aircraft. Boeing has looked at strutted wings that mount across the top of the aircraft and then you could get the rotor underneath them.

‘The other approach that we’ve been looking at with Boeing is to put them right at the back of the aircraft… so the fans themselves actually hang right off the back behind the tail. That’s a challenge to the overall aircraft design in terms of mounting them but also the centre of gravity. The aircraft gets a bit back-end loaded and you don’t want to be carrying concrete around in the nose to compensate for that so you’ve got to start significantly changing the aircraft design.’

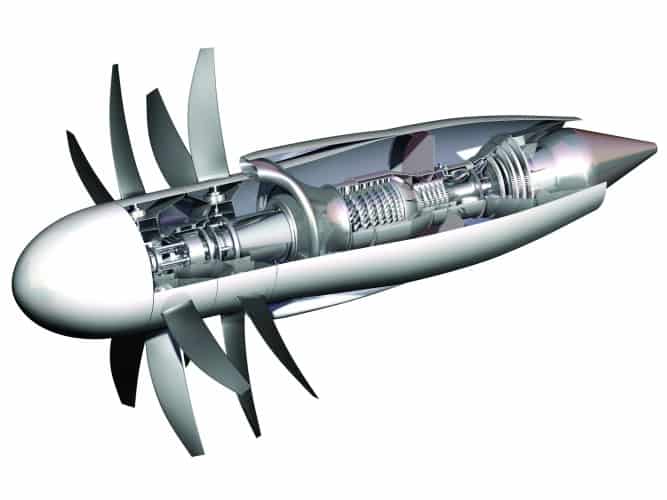

The open-rotor engine concept, which Rolls has been examining on and off for three decades, is seen as one possible future in the company’s 20-year vision. The design uses two contra-rotating fans that are wider than those of current engines to expel more air more slowly, achieving similar thrust speeds with less energy and so improving efficiency and fuel-burn. But doing away with the casing in order to sufficiently reduce weight from the larger fan design inevitably increases the noise. And it’s here that the future of the engine comes into doubt, not due to technology — an open-rotor engine would likely take only 10 years to develop — but politics.

Develop the open-rotor and we’ll bank the fuel savings for global warming

‘The testing we’ve done says that an open-rotor engine with modern aerodynamics and low tip speed would meet current noise requirements, so it would be significantly quieter than any of the engines flying today,’ said Parker. ‘If the next requirement is seven decibels lower we think we can still meet that but if the next one is seven decibels down again then forget it… It’s going to be an emotive issue but people aren’t going to be willing to invest that much more in the technology until somebody says “here’s the minimum noise requirement for the next 40 years — develop the open-rotor and we’ll bank the fuel savings for global warming”.’

In the meantime, Rolls-Royce is concentrating on evolutions of the Trent engines that use a new carbon/titanium composite to reduce weight by up to 680kg per aircraft. The ‘Advance’ engine will decrease fuel burn and CO2 emissions by 20 per cent compared to the first generation of Trent engines and could be ready for entry into service from 2020. The follow-up ‘UltraFan’ introduces a variable pitch fan system and a gearbox to cope with the even larger blade size and slower rotation speed, ostensibly the most dramatic engine design change for decades and one that paves the way for an open-rotor model.

But creating new materials such as this is a major challenge, explained Parker. ‘They can stand the heat of the environment but other elements, particularly water vapour, can attack them, so you’ve got to combine the ceramic composite with the right coatings to protect it. But there’s a big prize if you can because they can operate at much higher temperatures than the metals we use today, so you’re not having to use all the cooling air that is wasted in the cycle.’

The other big technological challenge for Rolls-Royce in aerospace is not in the engines themselves but the systems that surround them. First, this means developing sensors that can capture and send real-time information on how the engines are operating, and then working out how best to use this ‘big data’. ‘Each engine out there would generate 1TB of data a year if we were able to gather all of that and use it,’ said Parker. ‘At the moment the problem is connectivity: you can’t get that data off an aircraft while it’s flying. Perversely we seem to be getting close to the point where you can stream a movie up to an aircraft and watch it live but the data path in the opposite direction is rather restricted.’

The challenge and the opportunity of big data is, when something does happen unexpectedly, being able to play back the whole scenario or look at several engines that have had the same problem

The challenge after that is developing algorithms that can spot novelties in the data that can enable engineers to identify trends or events that inform their understanding of how an engine is performing and what may be going wrong. ‘The challenge and the opportunity of big data is, when something does happen unexpectedly, being able to play back the whole scenario or look at several engines that have had the same problem,’ said Parker. ‘Is there something common that we maybe could have spotted a month or two months before that would have said ‘watch out’.’

Second, it means coping with the increasing use of electrical systems on aircraft. This could well mean eventually moving to a hybrid-electric propulsion model, perhaps using a gas turbine to generate electricity to power the aircraft and even the engine fans. Rolls-Royce has begun this process by collaborating on the ‘E-Thrust’ study with Airbus and Cranfield University, as well as using a number of its other university technical centres to start researching different aspects of electric aircraft.

‘The big challenge is to make them light enough they’ve probably got to be super-conducting systems, so the cryogenics all needs to get smaller and lighter before it will happen,’ said Parker. ‘We know fundamentally from the studies we’ve done enough to say we’re not breaking any laws of physics. So it is about innovation and technology and driving systems to be smaller and lighter and more efficient, but it’s not unobtainable.’

Despite these broad horizons, Rolls-Royce has actually been narrowing its business focus for several years now, selling off its energy-sector divisions, including both its experiments with tidal generation and its long-standing industrial gas turbine company. However, the firm has now stated its desire to diversify again, and through organic growth rather than buying new companies. The nuclear business, which supplies reactors for the Royal Navy’s submarines and control and monitoring equipment for France and China’s civil power plants, is eyeing up the UK’s resurgent atomic energy sector.

The UK currently has seven nuclear power plants and they all need replacing by 2025. We could easily handle a lot of the advanced manufacturing of that

Why get out of one sector of the energy market just to go back into another part of it? ‘[In gas turbines] we were a very small player and didn’t have the network to support or even win the customers,’ said Parker. ‘Nuclear doesn’t have the volume of small gas turbine production. The UK currently has seven nuclear power plants and they all need replacing by 2025, just to keep our current proportion of nuclear energy. So we could easily handle a lot of the advanced manufacturing of that. We’d need to build a new factory and we’ve had that discussion with the government.’

This is a big opportunity to lead this area for the world and be in a very strong position

The firm has signed agreements with two of the three developers in the UK’s new nuclear programme to help build the pressurised water or boiling water reactors.

But with some expecting Britain to increase its proportion of nuclear generation from the current 17 per cent to around 30 per cent, Rolls-Royce thinks there is another prize: small, 200–300MW modular reactors as an alternative to the kind of 1.GW large-scale power plants currently planned. ‘This is a big opportunity to lead this area for the world and be in a very strong position,’ said Parker. ‘You can make a lot of the small reactor modules in a factory, deliver them to the site and have them up and running in three years compared to seven or eight. Also that means it’s a smaller capital investment that’s tied up for less time before it starts earning any money.

‘From a network point of view, [with] a 1.6GW power station you’ve got to put a whole new grid in to distribute that amount of power, whereas with a 300MW unit you can put one or two in an existing [offline] coal-fired power station. You’ve got all the buildings and the infrastructure there, you just drop a couple of these small modular reactors in and you carry on generating. And the other one in terms of an international market is non-proliferation. You can make the small modular reactors as what I would call almost a nuclear battery so it’s almost tamper-proof. It’s small enough and portable enough that you can reprocess that at a base and give them a new one.’

It’s a wildly ambitious plan, but Rolls-Royce has been a world leader in nuclear power since its birth. Given the firm’s determined success in dominating highly complex niche technology markets, it would probably be foolish to be against it.

Ric Parker, director of research & technology, Rolls-Royce

Education

- 1978 BSc Physics, Imperial College London

- 1992 MBA with Distinction, Loughborough University

Career

- 1978 Joined Rolls-Royce, progressing to various posts including chief of composites and ceramics, chief of compressor engineering, managing director – compressor systems

- 2001 Appointed director of research & technology for Rolls-Royce

- 2006 Appointed Visiting professor in aerospace and transport technology at Loughborough University

- 2013 Awarded the CBE for “Services to Engineering”

- 2013 Made vice-president of the Royal Academy of Engineering

- 2013 Received honorary doctorates from Loughborough University and Nanyang Technical University, Singpaore

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...