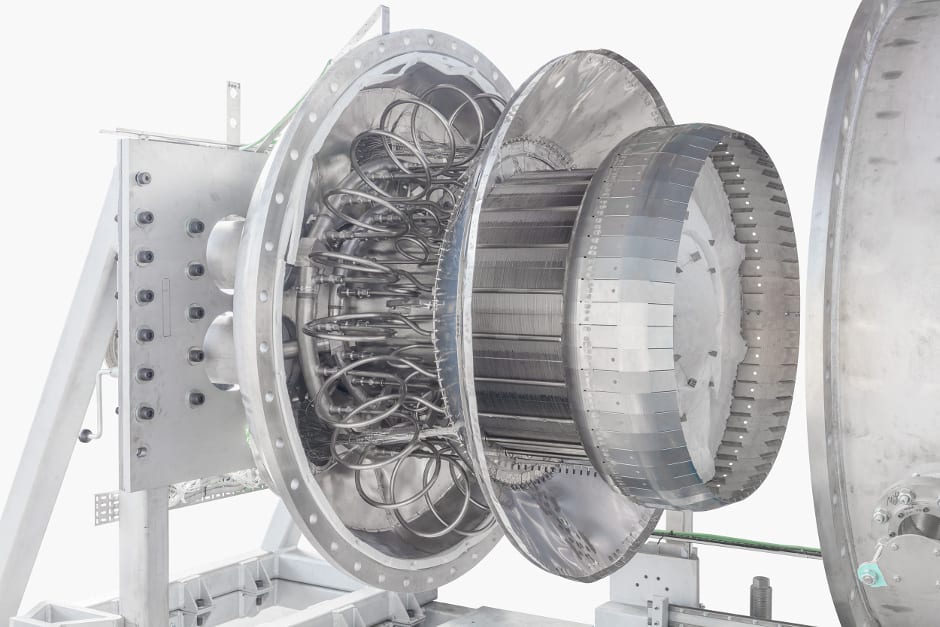

Reaction Engines’ precooler heat exchanger passed all test objectives in the first phase of high-temperature testing designed to directly replicate supersonic flight conditions.

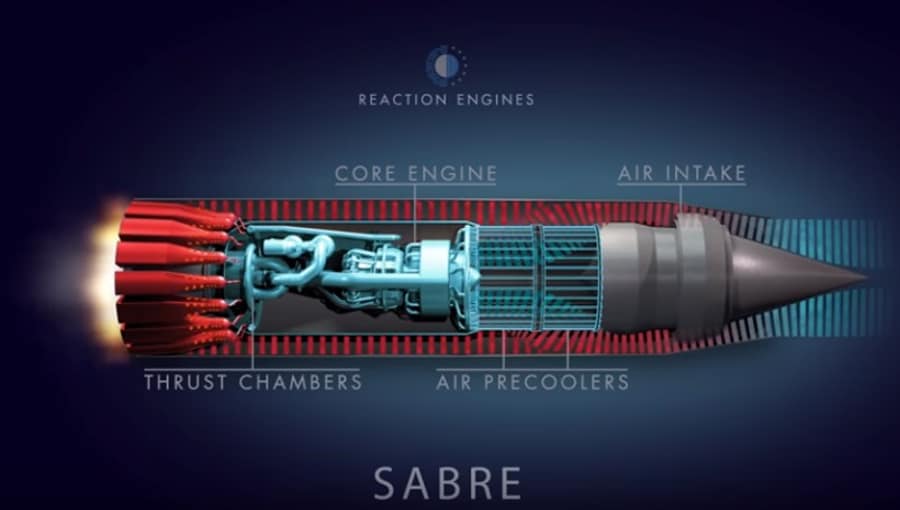

The precooler is a key element of Reaction Engines’ SABRE (Synergetic Air-Breathing Rocket Engine) hydrogen-fuelled engine, which uses atmospheric oxygen in its combustion cycle, switching to an onboard supply of liquid oxygen once out of the atmosphere. The precooler ensures that the engine core runs with cold inputs and keeps the core components cool despite the heating effect of its high velocity.

The ground-based tests saw the precooler quench the 420°C intake airflow in less than 1/20th of a second. The intake temperature replicates thermal conditions corresponding to Mach 3.3 flight, which matches the speed record of the SR-71 Blackbird aircraft, the world’s fastest jet-engine powered aircraft.

Reaction Engines said the tests are the first phase in a test programme that will see the precooler test article (HTX) exposed to high-temperature airflow conditions in excess of the 1,000°C expected during Mach 5 hypersonic flight.

The testing milestone took place at Reaction Engines’ TF2 test facility located at the Colorado Air and Space Port, US. The TF2 test facility has been constructed by Reaction Engines to undertake ground-based ‘hot’ testing of its precooler technology. The technology has already passed tests in the UK where its performance was validated at ambient air temperatures.

Mark Thomas, chief executive, Reaction Engines, said: “This is a hugely significant milestone which has seen Reaction Engines’ proprietary precooler technology achieve unparalleled heat transfer performance. The HTX test article met all test objectives and the successful initial tests highlight how our precooler delivers world-leading heat transfer capabilities at low weight and compact size. This provides an important validation of our heat exchanger and thermal management technology portfolio which has application across emerging areas such as very high-speed flight, hybrid electric aviation and integrated vehicle thermal management.”

To replicate the conditions the precooler will experience at hypersonic speeds, the TF2 test facility uses a General Electric J79 turbojet engine formerly used in a McDonnell Douglas F-4 Phantom aircraft to provide high-temperature airflow. Engineers at Reaction Engines’ Culham headquarters constructed the HTX precooler test article and after initial testing it was shipped to Colorado at the end of 2018, with ‘hot’ testing commencing in early March 2019.

In addition to the hot precooler tests being conducted in the US, Reaction Engines is in the final stage of constructing its TF1 test facility at Westcott, Buckinghamshire, where it will undertake ground-based testing of a SABRE engine core.

From the archive

https://www.theengineer.co.uk/skylon-and-sabre-your-questions-answered/

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...