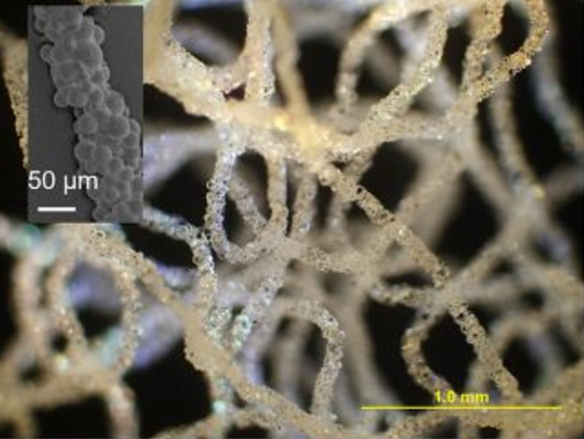

(Credit: NC State)

Published in Advanced Materials, the work involved printing silicon rubber structures by combining water with solid and liquid forms of silicon into a pasty ink. When printed, the team found that the liquid silicon rubber acted as a bridge for the tiny silicon rubber beads, helping to link them together like water helps sand particles bind in sand castles. According to the researchers, the resulting flexible and porous structures could have biomedical applications and uses in soft robotics.

"There is great interest in 3D printing of silicone rubber, or PDMS (polydimethylsiloxane), which has a number of useful properties," said Orlin Velev, professor of chemical and biomolecular engineering at NC State. "The challenge is that you generally need to rapidly heat the material or use special chemistry to cure it, which can be technically complex.”

"Our method uses an extremely simple extrudable material that can be placed in a 3D printer to directly prototype porous, flexible structures - even under water. And it is all accomplished with a multiphasic system of just two materials - no special chemistry or expensive machinery is necessary. The 'trick' is that both the beads and the liquid that binds them are silicone, and thus make a very cohesive, stretchable and bendable material after shaping and curing."

As the technique works in wet and dry environments, the team believes it has the potential to be used in live tissue, such as for flexible meshes or soft bandages that could be applied or even printed directly on the human body.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...