Such batteries have the potential to store electricity at up to five times the energy density of lithium-ion batteries but inherent shortcomings have thwarted their development.

Researchers at the University of Illinois at Chicago have helped prove that a new prototype is powered by a chemical reaction that may solve the new battery's biggest drawback.

The findings are reported in the January 11, 2016 issue of Nature.

Current lithium-air batteries - in which the metallic lithium of the anode reacts with oxygen from the air – store energy in the form of chemical bonds of oxide compounds. Versions tested to date have stored and released energy from lithium peroxide, an insoluble substance that disrupts the battery's electrode.

Battery scientists at the US Department of Energy's Argonne National Laboratory developed a prototype that they claimed had the ability to produce only lithium's superoxide, not peroxide, as the battery discharges. Unlike lithium peroxide, lithium superoxide breaks down into lithium and oxygen, thereby offering the possibility of a battery with high efficiency and good cycle life.

The Argonne group has designed the battery to consume one electron rather than two and produce the superoxide, said UIC's Amin Salehi-Khojin, assistant professor of mechanical and industrial engineering. But it was difficult to prove the reaction took place.

"Ex-situ analysis is not accurate enough to prove such a big claim," he said in a statement.

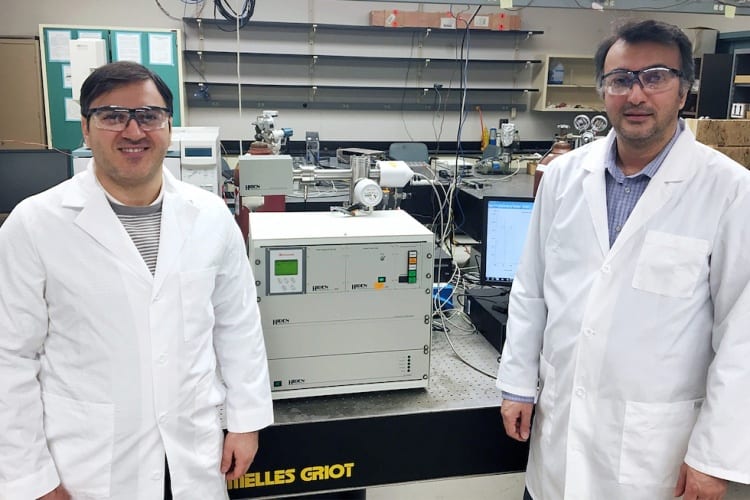

Salehi-Khojin and postdoctoral research associate Mohammad Asadi devised a mass spectroscopy apparatus to measure the electrochemical reaction products in situ during charging or discharge of the battery. The system operates in ultra-high vacuum and is very sensitive to the tiniest change in oxygen concentration, said Asadi, who is one of five first authors on the paper in Nature.

For the first time, the UIC researchers were able to show that one electron per oxygen atom was produced, indicating lithium superoxide, not peroxide, was forming in the battery. They were also able to show that no other lithium compounds were generated as side-products.

"This is going to be a valuable system for continuing the study of this battery and other types of metal-air batteries," said Salehi-Khojin. "Not only can we analyze the products of the electrochemical reaction, we can elucidate the reaction pathway. If we know the reaction pathway, we'll know how to design the next generation of that battery for energy efficiency and cost effectiveness."

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...