Wednesday evening saw a repeat of a BBC4 programme I missed when it originally aired back in August. Britain’s Nuclear Secrets: Inside Sellafield was an hour-long retrospective on the UK’s nuclear history and the central role of the Cumbria site. The affable Professor Jim Al-Khalili took us on a journey through Britain’s nuclear age, from the Windscale reactors used to develop plutonium for the UKs first nuclear weapons, to the 1957 fire, the proliferation of cheap nuclear energy in the 1970s, and the Thermal Oxide Reprocessing Plant (Thorp) that still operates today at Sellafield.

Coincidentally, I had spent Wednesday morning at a press conference where Sellafield was the primary point of discussion. Officials from the Nuclear Decommissioning Authority (NDA) were joined by several academics to talk about the options for dealing with the 140 tons of plutonium that are currently stored at the site. The largest stockpile of civil plutonium in the world, it presents a multitude of problems and opportunities. Which outweighs which depends very much on who you speak to, and how optimistic you are in relation to the development of certain technologies.

It takes somewhere in the region of 5-10kg of plutonium to make a nuclear weapon, so 140 tons is a slightly worrying amount to have sitting in a concrete shed in Cumbria. While everyone at the press conference was at pains to point out that there are no major safety concerns with the current storage, it is widely accepted that a long-term plan needs to be formulated. This, however, is where things get tricky. The potential energy of the plutonium if converted to nuclear fuel is massive, but there are several competing technologies vying for endorsement, none of which are well proven as financially viable.

Top of the list – and the government’s current preference – is for some application that uses mixed oxide fuel, or MOX. MOX is made by blending plutonium with natural or depleted uranium to create a fuel that is similar, but not identical, to the low-enriched uranium used in most nuclear plants today. MOX can be – and in several European countries is – used in thermal reactors alongside uranium. But despite past concerns, there is in reality no shortage of uranium today, so no huge need to supplement it with MOX in current reactors. Where MOX could in fact lead to greater efficiencies is in fast reactors, but these are costly and difficult to operate, and would not make economic sense unless the cost of uranium fell.

To complicate matters further, developing MOX is by no means a straightforward process. A Sellafield MOX Plant was completed in 1997, didn’t actually begin operation until 2001, and was closed in 2011 after a poor performance record that saw it deliver just 5 tons of MOX in its first five years. To put that it into context, it was designed with a capacity for 120 tons a year. Total construction and operating cost was around £1.2bn. While France has had a degree of success in producing MOX, construction on the US’s MOX production facility at the Savannah River Site was recently pushed back a decade, and may not be in operation until 2033.

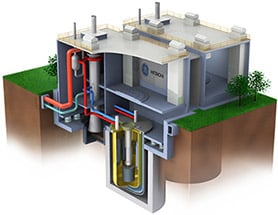

Another option on the table is PRISM. Developed by GE Hitachi (GEH), PRISM is a sodium-cooled fast reactor that uses a metallic fuel alloy of zirconium, uranium, and plutonium. GEH claims PRISM would reduce the plutonium stockpile quicker than MOX and be the most efficient solution for the UK. The problem is, despite being based on established technology, a PRISM reactor has yet to be built, and the UK is understandably a little reluctant to commit in this direction. Seen as something of a gamble, it remains in the running alongside the currently more favoured MOX option.

Amid all the uncertainty, one thing is for sure. Regardless of what decision is taken, a proportion of the plutonium will end up as waste and will need to be safely disposed of. One of the speakers at the press conference was Professor Neil Hyatt from the University of Sheffield. A materials science specialist, Hyatt is currently developing an immobilisation technique that can be used to render the plutonium unsuitable for weaponisation, allowing it to be more safely stored in the longer term. Using a form of hot isostatic pressing (HIP), the process mimics the formation of ancient minerals by using extreme heat and pressure to lock the plutonium inside ceramic based wasteforms.

According to Hyatt, the HIP technology is about a decade away from operation. Unlike MOX and PRISM, immobilisation has no prominent industry backers. In comparison to exploiting the plutonium for our energy needs, there is no great fortune to be made from disposing of it safely. But immobilising the entire plutonium stockpile may in fact be a more economically sound approach than reprocessing, says Hyatt. Some see this as madness, putting all that potential energy beyond the use of future generations. Others believe the technology needed to exploit that energy is decades away, by which point fusion and renewables will be better options. Just about the only thing the NDA could say with certainty, was that the right decision is more important than a quick one. We wait with bated breath.

RIA launches strategic vision for 2050 rail network

I think the main benefit of HS2 was to free up capacity on the existing lines for freight or additional passenger journeys, but the time savings were...