The project, being led by Dr Nicola Everitt (pictured below) at Nottingham University alongside researchers at Nile University in Egypt, is aimed at developing an alternative to oil-based plastics for use in packaging.

By developing the biopolymer bags, the researchers hope to help reduce the significant waste problem in Egypt, as well as producing a new food packaging material to extend the shelf life of products in countries including Britain.

“Only around 50 to 60 per cent of Egypt’s waste is actually collected, and the rest lies around in plastic bags at the end of the street and by the roadside,” said Everitt.

To develop the bags, the researchers are investigating the use of chitosan, a man-made polymer derived from the organic compound chitin, which is extracted from the shrimp shells. Shrimp shells are themselves part of Egypt’s waste problem.

Chitosan is a promising biodegradable polymer, which is already used in pharmaceutical packaging due to its antimicrobial, antibacterial and biocompatible properties.

From each kilogram of dried shrimp shells, the researchers hope to make 10-15 biopolymer bags.

The shells are first washed and then boiled in acid to remove the calcium carbonate “backbone” of the crustacean. They are then washed again before being bathed in an alkali, to remove protein from the material, leaving the long molecular chains that make up the biopolymer.

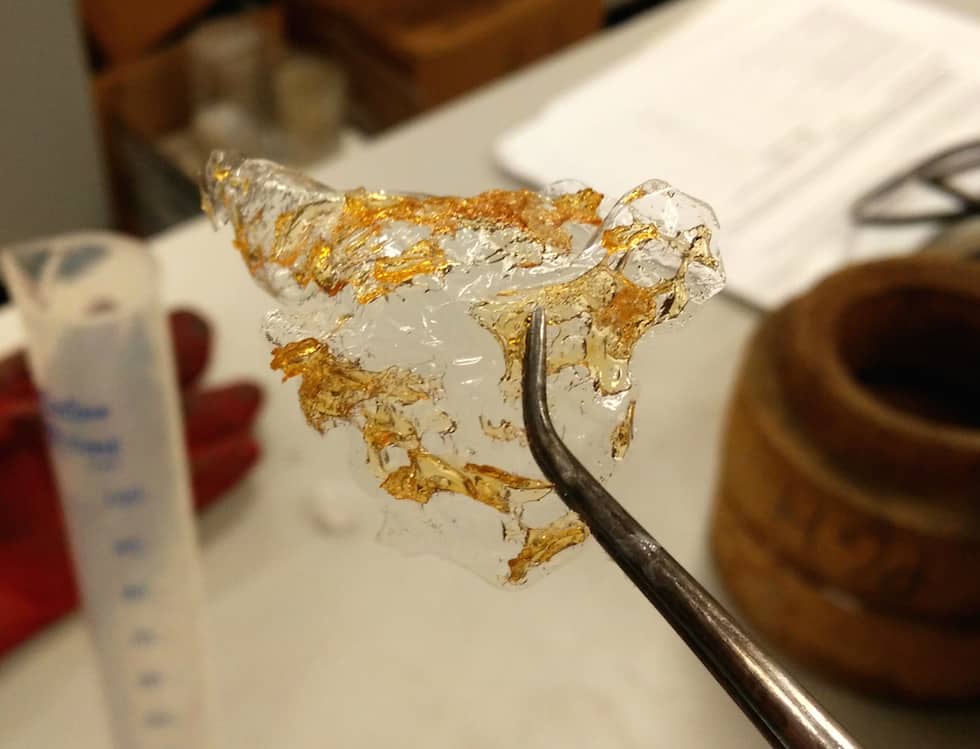

The dried chitosan flakes can then be dissolved into solution, and made into a polymer film using conventional processing techniques.

The researchers also plan to investigate the use of the material to develop an active polymer film capable of absorbing oxygen, for use as food packaging. The packaging could offer a low energy method of improving the shelf life of foods, thereby reducing waste.

“The packaging would be used to control the atmosphere around the food,” said Everitt. “Gases are quite often put in around food to try to preserve its shelf life, and people are looking at materials to hold in that atmosphere, but perhaps let other gases out,” she said.

By creating certain holes between the molecular chains of the biopolymer, the researchers hope to create a way to filter out these gases.

The project is sponsored by the Newton Fund.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...