Imagine living next to an airport where the aircraft are taking off and landing all night, but you never hear a thing?

That is the promise of hybrid aircraft, in which a small jet engine is combined with a battery and an electric motor to drive the propellers. Such aircraft could also consume up to 50 per cent less fuel, according to Siemens.

The company, which is working with Airbus, ultimately hopes to launch 90-seater civilian hybrid-electric aircraft into the skies by 2035.

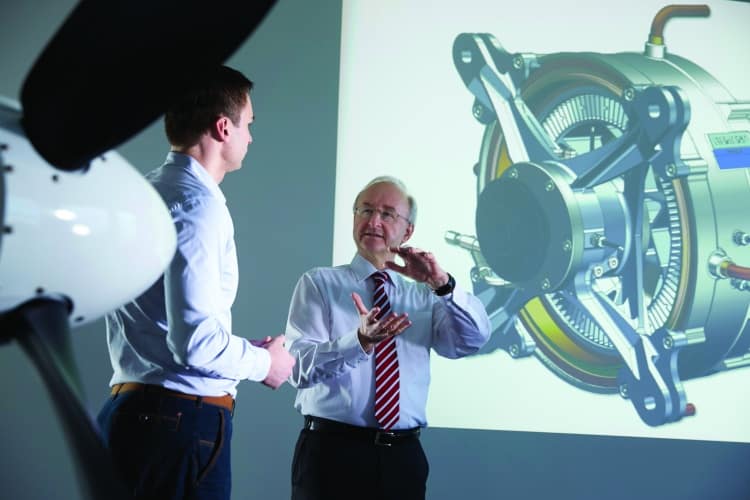

But the technology must first be proven on smaller aircraft. To this end, Siemens has recently developed an electric motor with a weight of 50kg and a continuous power output of 260kW – enough to fly a four-seater aircraft with a take-off weight of two tonnes, when used in conjunction with a small jet engine.

”If you start purely electrically, and only switch on the combustion engine after some time, you will have no noise from the battery, and only a little propeller noise, which you can reduce by turning the propeller more slowly. In this way, you can make a really very quiet aircraft.

Frank Anton, head of electric aircraft at Siemens

The motor has a power-to-weight ratio of 5kW/kg, said Frank Anton, head of electric aircraft at Siemens. “That is a factor of five higher than a normal industrial motor.”

A hybrid design would allow aircraft to receive an additional power boost from the battery during take-off and climb. Not only would this reduce the size of the engine needed for cruising, when the power demand is much lower, but it would also allow it to operate constantly at its most efficient speed, according to Anton.

“Overall, we would expect a reduction of fuel consumption of 25 per cent,” he said.

The motor also has a rotational speed of 2,500 revolutions per minute, allowing it to drive the propellers directly. This offers greater flexibility when distributing the propulsion system around the aircraft, added Anton, including the location of the propellers themselves.

“So, for example, there is an electric aircraft called the e-Genius [developed by researchers at the Institute of Aircraft Design at Stuttgart University], where the propeller is on top of the stabiliser at the tail of the aircraft,” said Anton. “This is very good from the point of view of propeller efficiency, and also allows the propeller to be larger than normal and turn more slowly, which also makes it much more efficient.” This could reduce fuel consumption by a further 25 per cent, he explained.

What’s more, larger propellers that turn more slowly are much quieter than conventional designs, Anton added. “So if you start purely electrically, and only switch on the combustion engine after some time, you will have no noise from the battery, and only a little propeller noise, which you can reduce by turning the propeller more slowly,” he said. “In this way, you can make a really very quiet aircraft.”

To design the synchronous motor, the company used advanced simulation tools, allowing its engineers to trade off improvements in one aspect of its operation with compromises in other areas.

“So while you are optimising the magnetics, you have to think about how you can cool them, and if you optimise the cooling, you need more space so you have to compromise on the magnetics,” Anton said.

“And then again while you are improving the magnetics you need to carry stronger forces, so you need more material, and the motor becomes heavier, so then again you have to work on the mechanics, on the structural analysis.”

To reduce the weight of the motor, the device’s four permanent magnets are arranged next to each other in such a way as to ensure that the orientation of each field is in a different direction. This arrangement, known as a Halbach Array, allows the magnetic flux to be directed so as to achieve the highest power output with minimal use of material.

”It is very encouraging to see large manufacturers taking an interest in more electric technology. Clearly they are making significant developments

Christopher Gerada, professor of electric machines at Nottingham University

To reduce the weight of the motor’s cooling systems, the company also used direct-cooled conductors. Any heat lost from the copper conductors is discharged directly into an electrically non-conductive cooling liquid, such as silicone oil.

The motor appears to have a good power density, according to Christopher Gerada, professor of electric machines at Nottingham University. “It is very encouraging to see large manufacturers taking an interest in more electric technology,” he said. “Clearly they are making significant developments.”

A great deal of work is going on among the research community and industry to improve the power densities of electric motors, said Gerada. “High power density and torque density are critical, because you can save material and get more power,” he said. “And for any transportation system, any weight saved is less fuel spent.”

To this end, he and his colleagues have developed a motor with a power density of approximately 30kW/kg. The motor was developed for use as an electric starter-generator in a project with French business jet manufacturer Dassault Aviation, as part of the European Commission-funded Clean Sky programme.

The researchers are also working on a number of other projects to develop more electric aircraft. One way in which electric motors can be used to reduce fuel consumption and emissions, for example, is while aircraft are still on the ground.

Working with aerospace component manufacturers Honeywell and Safran, the researchers have developed an electric motor that is integrated into one wheel on each of an aircraft’s main landing gear, to provide power during taxiing on the runway. The system, known as EGTS, is powered by the aircraft’s auxiliary power unit (APU).

Gerada and his team are also working with Safran on a future version of the ETGS system.

“Today, most movement on the ground is powered through the main engines, but these are designed to operate at 30,000–40,000ft,” said Gerada.

The higher air density on the ground, coupled with the fact that the engines are only operating at idle speed when moving around the runway, means that they are working very inefficiently.

“So they are wasting fuel, and making noise and pollution on the ground,” he said. “With the forecast increase in air traffic over the coming years, trying to reduce emissions while the aircraft is on the ground and maneuvering is quite critical.”

Having a motor integrated into the wheel of the aircraft, and powered by the APU, can reduce fuel consumption and pollution levels significantly, he added.

Ultimately then, the next generation of high-density electric motors could allow aircraft to move around much more quietly and cleanly – both on the ground and in the air.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...