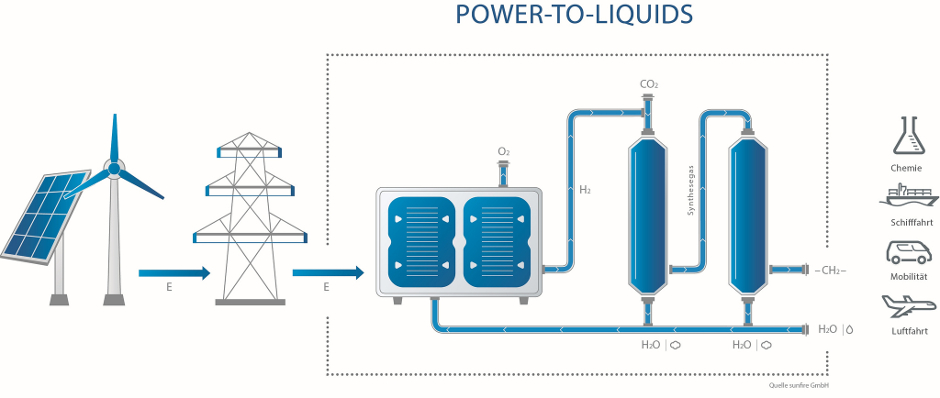

Dresden-based Sunfire has developed a high-temperature co-electrolysis technology, which uses water, carbon dioxide and green electricity to produce synthesis gas.

The system, developed as part of the Kopernikus project Power-to-X and funded by the German Federal Ministry of Education and Research, has been successfully tested for over 500 hours.

Previously, a two-stage process has been needed to break water vapour down into hydrogen and oxygen and to turn carbon dioxide into carbon monoxide, through electrolysis and the reverse water-gas-shift reaction.

In contrast, the co-electrolysis process recovers hydrogen and carbon monoxide in a single-step process, significantly improving the efficiency of the overall process and lowering costs.

The system is based on a ceramic ion transport membrane, which conducts oxygen ions, rather than hydrogen ions or hydroxide ions. In this way it can be used to reduce both steam and carbon dioxide, according to Karl Hauptmeier, senior product manager at Sunfire.

“Since we are working with oxygen, it gives us the capability to also reduce CO2, so we are not limited to hydrogen-based compounds,” said Hauptmeier. “We can separate the oxygen out of the water vapour and out of the CO2, which gives us the opportunity to do this in a one-step electrochemical process.”

Within the next few weeks, the Sunfire-Synlink system will be delivered to project partner, the Karlsruhe Institute of Technology (KIT).

There, the system will be combined with direct air capture technology developed by Climeworks, which filters carbon dioxide out of ambient air.

This CO2 will then be combined with steam, and supplied to the co-electrolyser unit, which reduces the two feedstocks to a hydrogen and carbon monoxide mixture syngas.

This gas will then be processed in a micro Fischer-Tropsch Synthesis system, developed by INERATEC, which will combine the hydrogen and carbon monoxide into hydrocarbons.

Finally, hydrocracking technology from KIT will convert the hydrocarbons into synthetic fuels.

The team plan to demonstrate the integrated production of e-Crude, a synthetic crude oil substitute, by the end of August 2019.

Sunfire has already begun scaling-up the high-temperature co-electrolysis process to an industrial scale, as part of the SynLink project, funded by the German Ministry of Economics and Energy.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...