The coating, made from rough nanoporous tungsten oxide, is capable of repelling liquid even after it has been subjected to sustained structural abuse. It was developed in the lab of materials science professor Joanna Aizenberg, whose team has been working on Slippery Liquid-Infused Porous Surfaces (SLIPS) since 2011. The work is published in the journal Nature Communications.

“Our slippery steel is orders of magnitude more durable than any anti-fouling material that has been developed before,” Aizenberg said in a statement.

“So far, these two concepts - mechanical durability and anti-fouling - were at odds with each other. We need surfaces to be textured and porous to impart fouling resistance but rough nanostructured coatings are intrinsically weaker than their bulk analogues. This research shows that careful surface engineering allows the design of a material capable of performing multiple, even conflicting, functions, without performance degradation.”

The coating is applied using an electrochemical technique that deposits an ultrathin film of tungsten oxide islands on to the steel. As each liquid-repelling island is not structurally connected its neighbours, damage to one does not effect the integrity of others, and the steel retains both its durability and its anti-fouling properties.

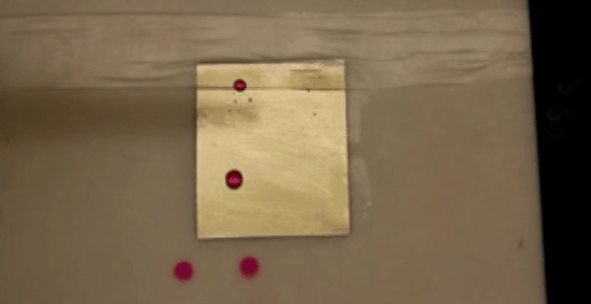

During testing, the team scratched the material with stainless steel tweezers, screwdrivers, diamond-tipped scribers, and pummeled it with hundreds of thousands of hard, heavy beads. A variety of liquids was then applied to the material to test its repellency, including water, oil, and biological fluids containing bacteria and blood. According to the researchers, all liquids were repelled, with the tungsten oxide actually making the steel stronger than steel without the coating.

It is claimed the material could have a wide range of applications, including non-fouling medical tools and devices such as scalpels and implants, as well as nozzle heads for 3D printing. The material could also have larger scale applications on marine vessels, where fouling can create drag leading to increased fuel consumption.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...