Viewpoint

Viewpoint

The UK is currently paying a heavy price for a lack of long-term commitment and strategic insight into its nuclear programme, says Gregg Butler

Almost half of Engineer readers think that a UK-developed small modular reactor (SMR) would be a better option than the current deal to build and operate a new nuclear power station at Hinkley Point, according to the conclusion of a recent poll on the website. Don’t we all! Had we but started this great programme around 1990, the world would indeed be our mollusc of choice. Only practicality and hard facts stand between this UK-centric wonderworld and reality.

Any nuclear reactor project takes a long time and continuity of purpose. UK nuclear policy has been the very inverse of this – in 2003 we announced a ‘no-nuclear’ energy policy, sold Westinghouse and its AP1000 in 2005, were thinking we might need some nuclear by 2006, and by 2008 were going hell-for-leather for 16GWe of new nuclear by 2025.

This timescale now meant existing, foreign-designed, reactors would be necessary but, even so, 12 or so reactors would surely give British industry the incentive to tool up and get involved. Strangely enough, 12 or so reactors of at least three different types doesn’t add up to the same opportunity.

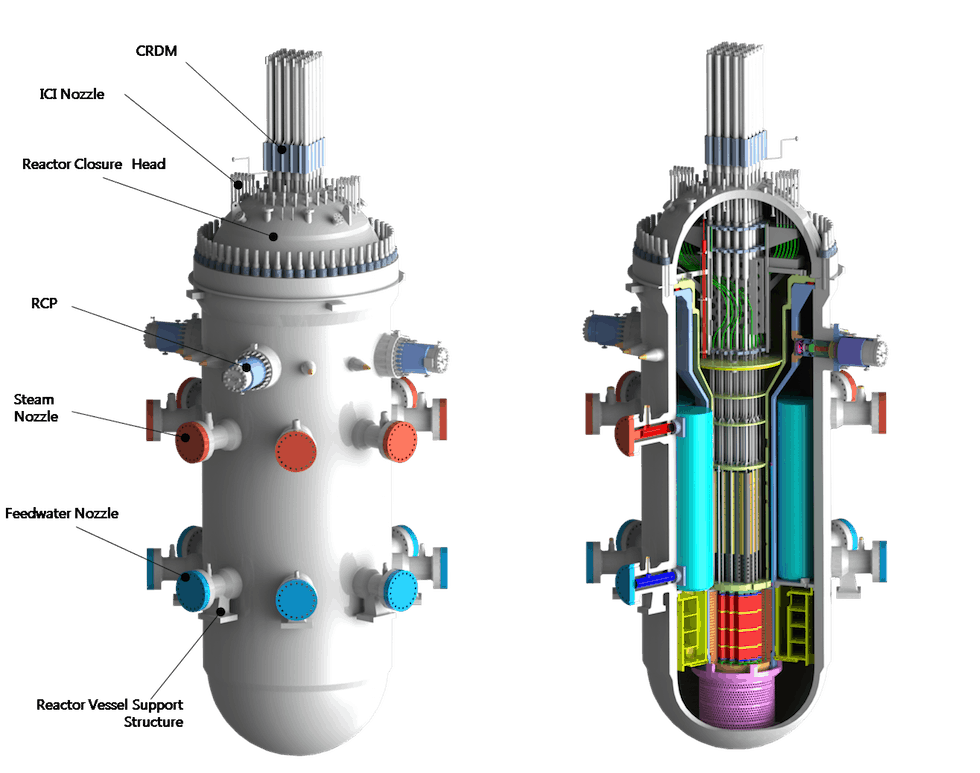

So what haven’t we tried and messed up yet? How about SMRs rolling off the production line like washing machines? And there’s the rub. SMRs eschew the classic economies of scale that drive the size of light-water reactors (of which pressurised water reactors [PWRs] such as the AP1000 and Areva’s EPR are a subset) upwards – conjecturally until they are so big you can no longer build them – and replace this with economies of number: in other words, make a large number of small reactors in a factory setting and simply transport them to the desired site. This makes a lot of sense, but the key is in the words ‘a large number’.

Developing reactors is not cheap and tooling up a factory to make them is also expensive. Moreover, the factory has to be commissioned and worked up to speed, so by the time the first true production SMR comes rolling off the line a lot of money will have been spent. And this will need to be offset by sales before anyone starts making money. The process makes very good sense for Volkswagen Golfs, as you’ve got a pretty shrewd assessment before you start that the market is there – and it’s the requisite large number.

So for our UK SMR what sort of numbers would we need? Well, best estimates for getting even the most developed of the existing (foreign-designed) SMRs ‘on the bars’ in the UK are around 2030, and if you transferred the whole of the 16GWe programme to, say, 250MWe small modular PWRs, then you would need 60. That’s the right sort of amount for economies of number, but it would require a total strategic focus for a UK programme and the unequivocal backing of a single SMR horse. Everything from the last 70 years of the UK nuclear industry (Magnox – 10 stations, nine designs; AGR – seven stations, four designs; PWR – one station, one design, and very different from the standard model) tells you this isn’t likely to happen. Of course, if you want a British design, add at least five years to the timescale, and worry that this will miss the prime energy need by over a decade.

Advanced designs are what we need. Which is the point where we find out that an advanced system marches at the speed of its lowest technology readiness level. For example, molten salt fast reactors might indeed be as cheap as chips and safe as houses, but they tend to need things such as online reprocessing, and they need to pump hot salt reliably for years – an interesting materials challenge and one never demonstrated. Regulators want evidence, flowsheets and demonstrable evidence. And comments that it worked okay in the US in 1983 in a slightly different form will not cut the mustard.

So what are we to do? Get on with the current Department for Business, Energy & Industrial Strategy (BEIS) competition, choose a single small modular pressurised water reactor design that can have a lot of UK manufacture, and announce a programme of, say, 20 of them after the current 16GWe of big ones. This would be enough of a home market to get the economies of number; getting the price low enough to access the world market. As a variant, you could also back one or two advanced systems at a low TRL level as a longer-term hedge. But do we have a clear idea why the programme is being supported, what future it is aimed at, what its success factors look like, and an unwavering long-term commitment? Unfortunately, this is called having a strategy and nothing in the last 70 years of UK nuclear power engenders a great deal of expectation that this will be the case.

Gregg Butler is head of strategic assessment at the Dalton Nuclear Institute, Manchester University

Red Bull makes hydrogen fuel cell play with AVL

Surely EVs are the best solution for motor sports and for weight / performance dispense with the battery altogether by introducing paired conductors...