The research, led by Prof Mike McGehee in the University of Colorado Boulder’s College of Engineering and Applied Science, uses a reversible metal electrodeposition process that differs from current industry standards.

Solar glass darkens as it converts light to electricity

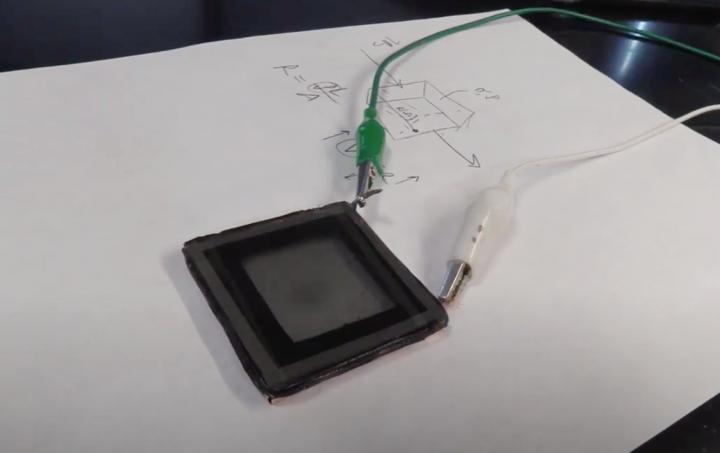

"What we are doing is building an electrochemical cell. We have a transparent electrode and an electrode with metal ions. By switching the voltage, the thin plate metal blocks the light," he said in a statement. "It's not at all how other people are achieving the same effect."

A paper by the team in Joule explains how metal can be electroplated onto a transparent electrode to block light and then stripped to make the window transparent again by manipulating the voltage. It specifically explores how various electrolytes can be used with different supporting anions to achieve the desired results.

Despite their appeal, dynamic windows have yet to achieve extensive commercialisation because of ‘their inability to simultaneously achieve fast, colour-neutral tinting over a wide optical dynamic range at a low cost’.

The new process is said to result in a more desirable neutral colour of glass than other technologies and allows for any transparency adjustment from 80 per cent tinted down to zero per cent or fully transparent. According to the University, many of the windows on the market can only provide up to 70 per cent tinting. This transition can be done quickly as well, with 60 per cent contrast happening in under three minutes.

The final product is also likely to be less expensive to create than existing technologies. McGehee said potential cost savings were hard to gauge but producing windows with this technology does not require large special tools and has a high throughput.

The team has made a one square-foot window using this process. They are currently running stability and other tests and the initial results indicate long-term durability with no evidence of electrode etching, which degrades the overall performance and is a drawback to other versions on the market.

Car manufactures are reportedly interested in the technology while Boeing already uses electrochromic windows on their 787 Dreamliner.

McGehee speculates that other application areas might include cycling glasses or ski goggles that shift with the quickly changing light conditions.

"This is a question and process my group has been looking into for some time now," he said. "This paper addresses many of the problems this technology has faced, and we think there is a lot of opportunity going forward."

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...