By making cells that contain their own oxygen, rather than relying on the proportion of oxygen in the air, the research team, which also includes members from Argonne National Laboratory and Peking University in Beijing, claim it have overcome many of the drawbacks that have previously plagued the development of this promising battery chemistry.

Lithium-air batteries have been a goal of energy researchers for over 40 years, because in theory they can store four times as much charge per kilogramme than lithium-ion cells. This has come at a price, however. The cells work by using oxygen to drive an electrochemical reaction with lithium in the battery’s electrodes; this oxygen is then released when the battery is discharged. But the non-oxygen components of air, especially carbon dioxide and water vapour, damage the electrodes; moreover, as the crucial reaction transforms oxygen from a gaseous phase into a solid one and then recharging changes it back; the gas-to-solid conversion consumes energy, reducing the battery efficiency; and both processes involve very large changes of volume that can dislodge connections inside the battery, reducing its life.

One particular problem is that it has always taken a higher voltage to charge previous lithium-air batteries than they can produce as output; typically the charging voltage is 1.2V higher than the discharge. “You waste 30 per cent of the electrical energy as heat in charging. … It can actually burn if you charge it too fast,” comments MIT research leader Ju Li.

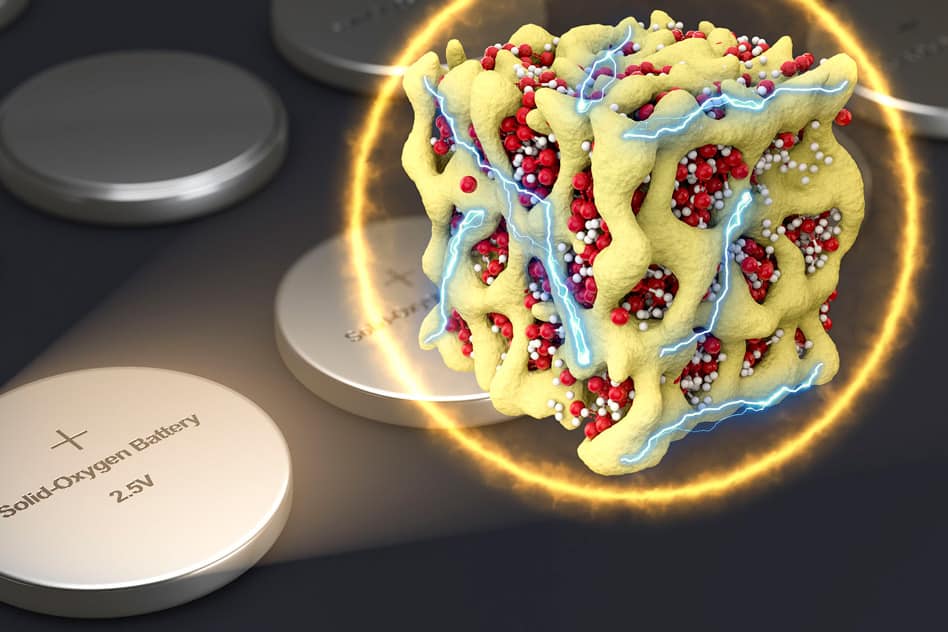

Li’s new variant gets around the problem of the oxygen phase-change by keeping the oxygen in a solid phase inside the battery’s structure. Rather than drawing in oxygen from the air, the cell contains nanometre-sized particles of a substance the researchers call nanolithia: a glass composed of three different lithium oxides, LiO2, Li2O2 and Li2O. Under normal conditions nanolithia would be very unstable, with the superoxide (LiO2) spontaneously breaking down to oxygen and lithium peroxide (Li2O2); but Li’s team stabilised it by embedding it in the pores of a cobalt oxide matrix which is saturated with liquid lithium carbonate that acts as the battery’s electrolyte, allowing charged particles to circulate around the cell.

In discharge phase the electrolyte reacts with the superoxide in the nanolithia, converting it into the other forms of lithium oxide; this frees electrons to flow in an outer circuit. Drives electrons the other way and the conversion reverses, regenerating the superoxide. The oxygen is never in a gaseous state; and because there is no air input to the battery, the system does not need scrubbing equipment to remove water vapour and CO2, which hampers conventional lithium-air systems.

In another advantage, the battery cannot be overcharged, because the reaction is self-limiting. “We have overcharged the battery for 15 days, to a hundred times its capacity, but there was no damage at all,” said Li.

In cycling tests, the team charged and discharged the battery 120 times, resulting in only a two per cent loss of capacity. And because the cobalt oxide-nanolithia cathode is lighter than conventional lithium-ion cathodes, Li believes that his batteries could store up to four times as much charge as a lithium-ion battery of the same size. The team expects to be able to make a practical commercial prototype within a year, which could be made as a direct drop-in replacement for lithium-ion batteries in applications such as electronic devices or electric vehicles. Li and colleagues describe their work in Nature Energy.

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?