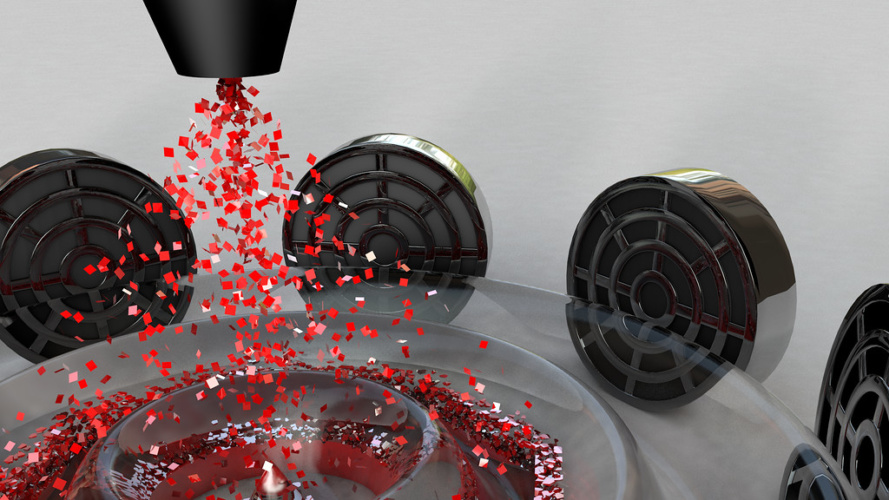

Known as ‘sonolithography’, the technology is the work of scientists at the Universities of Bath and Bristol. It uses commercially available transducers and electronics in combination with computer algorithms to manipulate ultrasonic acoustic fields, laying down precise and repeatable patterns of microscopic aerosol droplets on a substrate.

Soundwaves assist additive manufacturing with viscous liquids

“The power of ultrasound has already been shown to levitate small particles,” said Professor Mike Fraser from Bath’s Department of Computer Science.

“We are excited to have hugely expanded the range of applications by patterning dense clouds of material in air at scale and being able to algorithmically control how the material settles into shapes.”

In a paper published in Advanced Materials Technologies, the researchers outline how the technique could be adapted for a variety of different printing technologies. As the soundwave technology manipulates particles in mid-air without ‘physical’ contact, sonolithography is ideally suited to biofabrication, where tissue and cells are printed for advanced medical treatments.

“Sonolithography enables gentle, non-contact and rapid patterning of cells and biomaterials on surfaces,” said lead author Dr Jenna Shapiro, research associate in the School of Cellular and Molecular Medicine at Bristol University.

“Tissue engineering can use biofabrication methods to build defined structures of cells and materials. We are adding a new technique to the biofabrication toolbox.”

Bruce Drinkwater, Professor of Ultrasonics in Bristol University's Department of Mechanical Engineering, added: “The objects we are manipulating are the size of water drops in clouds. It’s incredibly exciting to be able to move such small things with such fine control. This could allow us to direct aerosol sprays with unheard-of precision, with applications such as drug delivery or wound healing.”

Beyond its applications in biomedicine, the team has shown the soundwave technique to be applicable to a variety of materials. Another particular area of interest is printed electronics, where ultrasonics can be used to arrange conductive inks into circuits and components.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.