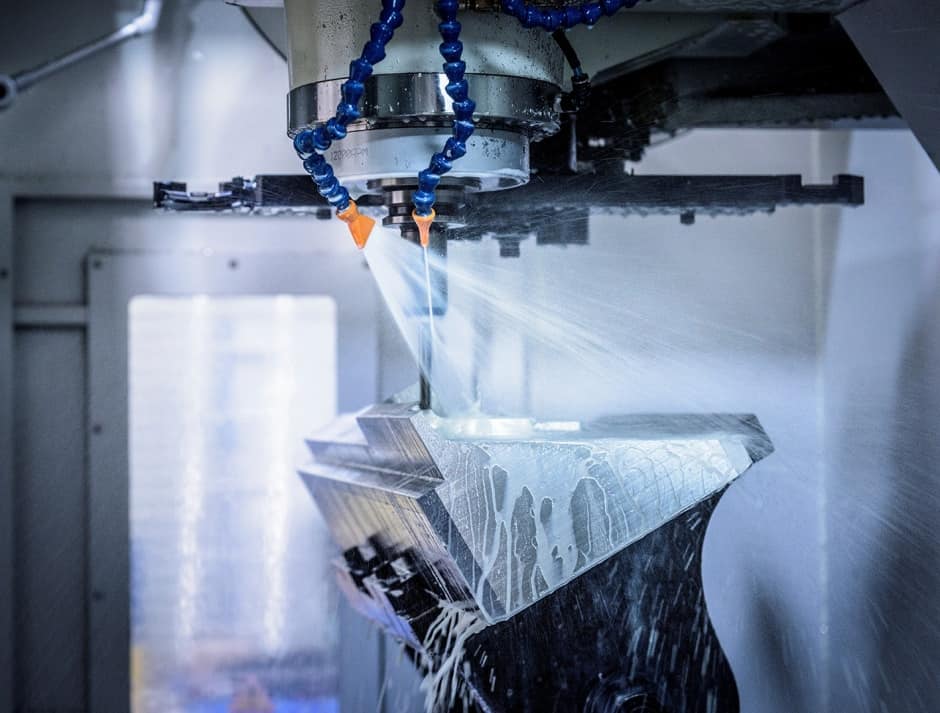

A selection of some the latest developments in the arena of machine tools

The UK’s largest machine-tool builder, Yamazaki Mazak, has signalled a renewed commitment to its UK manufacturing presence with major investment at its European manufacturing plant in Worcester. The plant opened in 1987 and produces more than 1,000 machine tools annually; as part of a programme to increase manufacturing capacity, Mazak has invested in two large machining centres from its Japanese factories. The Versatech machines will be used to precision-machine the cast-iron beds for all the machine tools manufactured in Worcester.

Marcus Burton, European group managing director, said: “This investment is a clear demonstration of Mazak’s confidence in our Worcester manufacturing facility and its dedicated workforce. There is an increasing demand across Europe for the new products that have been introduced and this latest investment is part of Mazak’s continuous investment strategy.”

The Versatech machines are multiple-surface, 5-axis double-column machining centres, among the largest in the Mazak range, specifically designed to tackle exceptionally large workpieces. “The new machines will significantly improve our capacity for heavy-duty precision machining operations in Worcester,” said Burton. “We anticipate a significant increase in productivity, due to the machine’s cutting feedrate and spindle speed, which will flow through to other areas of our manufacturing operations.”

While Mazak boosts capacity, other machine builders with a strong UK presence continue to launch new and improved products to meet the specific needs of UK manufacturing supply chain companies. DMG Mori, for example, has introduced a new turning centre to deal with large parts within a relatively small footprint. Its CLX350 lathe occupies under 5m2 of shopfloor space, but can turn components from bar up to 51mm diameter (65mm optional) and has a maximum turning diameter of 320mm; Z-axis travel is 530mm. Spindle speeds up to 5,000 revs/min can be programmed and the cartridge design means that exchange is simple and rapid. The machine has a VDI 30 turret with 12 tool positions, all of which can be driven on request; and can be augmented with modular additions, including automated workpiece handling.

Also with a nod towards the need to make productive use of space, specifically in small part turning and turn-milling, Citizen Machinery UK has launched the third generation of its compact R-Series sliding head machines. The latest R01 and R04 in Type-VI have bar capacities of 1mm and 4mm, with common front and back spindle modules and the ability to carry up to 17 tools. Floor area required is just 1,465 x 535mm. This expands the modular design concept being progressively introduced by Citizen, and the small frame construction aims to enhance rigidity and thermal stability, helping deliver precision for medical and miniature component production.

A need for stability is not confined to small components, and latest introductions from Starrag Heckert underline a claim to deliver “the most thermally stable horizontal machining centres available”. Heckert Solid Rock machining centres feature a combination of water-cooled main drive motors and ballscrews, plus a temperature-controlled structure, a natural granite machine bed and thermal compensation of the linear and rotary axes. Other UK launches of note addressing larger components include a portal, 5-axis machining centre, from Italian company Mecof, via NCMT. The UMILL 1800 is designed for aerospace, oil and gas, power generation and automotive applications.

Looking at activities among machine-tool users, there’s a growing awareness of changing opportunities, and SMEs such as Devon-based Investment Casting Systems (ICS) continue to look beyond historical markets and to invest in equipment to support these aspirations. ICS moved from general engineering subcontract work into toolmaking (and injection moulding services), and in 2016 set up a new division: Technical Composites Systems (TCS). Throughout these changes the company has looked to its principle machine-tool supplier, XYZ, for equipment and support.

“We bought our first XYZ machines, a Pro 2000 turret mill and a DPM bed mill 15 years ago and they are still with us today,” said technical director James Head. The company currently runs 12 XYZ machines, including four 1060 HS (high speed) vertical machining centres, said to be ideal for the toolroom. Confidence in these machines has a significant influence on overall productivity. Some of the larger mould tools have single programme cycle times of 75 hours, so ICS schedules these jobs for Friday afternoon, leaving them running over the weekend – and then leaving the machines free during manned hours to fit in shorter-cycle, more urgent work.

The latest machine to arrive is a 710 vertical machining centre, principally for composites work. “We created Technical Composite Systems to address opportunities in composite manufacturing,” said TCS director Mike Sloan. “What we have created is a comprehensive composite manufacturing facility for the aerospace and defence sectors that will maximise the synergy between our toolroom activities and the world of composites.”

Hurco has teamed up with honing specialist Bates Technologies to develop a high-precision honing process that can be carried out on standard machining centres. Benefits include cost reductions compared with purchasing and operating a dedicated honing machine; and the ability to combine general machining with honing on the same platform, eliminating a separate set-up. The process is performed on a Hurco VMX-series BT40 vertical machining centre. Diameter is rough bored to the correct size for honing, then a honing tool with a standard back end is exchanged automatically into the spindle and through-coolant is used to activate and control expansion of the tool.

Developments in tooling and workholding

A Matrix pin vice supplied by ETG (Engineering Technology Group) Workholding to Renishaw’s Digital Manufacturing Centre (DMC) is enabling a cost-effective solution when finish machining one-off, prototype and first-off complex free-form parts created using additive manufacturing. Traditionally, a fixture would have been developed via initial CAD drawing, prototyping, machining and assembly; using Matrix pin vices, Renishaw can create a part-specific, stable, secure and repeatable workpiece clamping configuration that can be set up in minutes. The pin vices are fitted to the tables on Fanuc RoboDrill D21L machining centres.

Horn’s 105 Supermini system is now available in new, high-performance versions featuring a new coating, substrate and microgeometry for boring, internal grooving, chamfering, threading, broaching, facing and parting-off exotic alloys and steels, including those that are structurally inhomogeneous. User benefits include improved productivity and significantly increased tool life.

Meanwhile, Sandvik Coromant has unveiled its CoroPlus suite of Industrial Internet of Things (IIOT) solutions aimed at helping manufacturers prepare for Industry 4.0. CoroPlus is the umbrella name for a new platform of connected tools and software; essentially comprising technologies that can send and/or receive data. The concept is designed specifically to improve the control of productivity and costs, through a combination of connected machining and access to manufacturing data and expert knowledge.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...