(Credit: Hongrui Jiang)

To trap the infrared light, the researchers used a material called black silicon, which is also highly effective at absorbing visible light and is commonly used in solar cells. Black silicon absorbs light because it consists of millions of nanowires all pointing upward like a densely-packed forest. Incoming light reflects back and forth between the vertical spires, bouncing around within the material instead of escaping.

The nanowires were made using tiny particles of silver to help etch the material down into a thin layer of solid silicon, which results in a thicket of microscopic needles that are taller than those which only absorb visible light. Both the nanowires and the silver particles contribute to absorbing infrared light. The stealth material was then transferred onto thin flexible substrates to create the IR stealth cloak.

"What we have shown is an ultrathin stealth 'sheet,'” said study leader Hongrui Jiang, professor of electrical and computer engineering at the University of Wisconsin-Madison.

“Right now, what people have is much heavier metal armour or thermal blankets. It's a matter of the weight, the cost and ease of use."

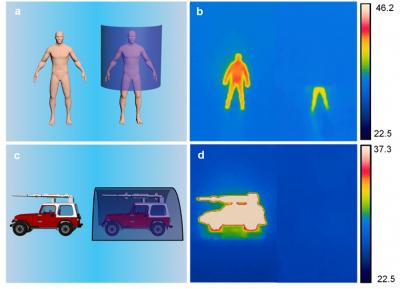

The work, published in Advanced Engineering Materials, showed that the nanostructures can almost completely conceal the thermal emission of people and objects. What’s more, Jiang and his team were able to embed the ultrathin sheets with micro‐emitters thermally isolated from the broadband absorbers that can present false thermography, potentially deceiving IR detectors and heat‐sensing cameras.

"You can intentionally deceive an infrared detector by presenting a false heat signature," said Jiang. "It could conceal a tank by presenting what looks like a simple highway guardrail."

The team is now working to scale up their prototype for real-world applications with assistance from UW-Madison's Discovery to Product programme.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...