The N-Visage technology, funded by the Nuclear Decommissioning Authority (NDA) and developed by REACT Engineering, was used by site engineers to predict potential sources of radiation in the plant’s shear cell, where fuel is sheared prior to being dissolved.

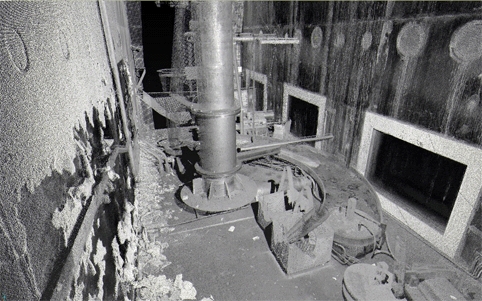

The team gathered information about the geometry of the facility using a 3D laser scanner to produce a high-resolution image similar to that of a black-and-white photograph.

This image was then combined with dose readings and fed into the N-Visage system, which ran thousands of calculations to create a detailed map of potential radioactive sources.

Project manager Tim Brentnall said: ’The resulting map of radiological distribution is extremely valuable in developing a safe decommissioning strategy.

“The resulting map of radiological distribution is extremely valuable to decommissioning”

’The great power of it is that once you’ve have this model of dose readings, you can say “what if we move that vessel?” Or “what if we shielded that pipe?” And put those scenarios into the model and recalculate the risks.’

REACT Engineering is now developing a 3D laser scanner to be used alongside a second, more compact, version of the system.

Brentnall said: ’A lot of the time you’ve got a very small hole that you can get into, maybe just a 6in diameter of penetration, to get into a shielded cave - so making this device as small as possible is our main goal.’

The NDA is in the process of revising its 2006 decommissioning strategy and is currently overseeing decommissioning activities at 20 sites across Britain, including Sellafield, Dounreay, Harwell and Sizewell A.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.