The device allows for magnets to be manufactured in complex forms that exhibit precisely engineered magnetic fields. 3D printing magnets in this way could open up possibilities across a range of applications, from location services to biomedical imaging.

"The strength of a magnetic field is not the only factor," said Dieter Süss, head of the Christian-Doppler Advanced Magnetic Sensing and Materials laboratory at TU Wien.

"We often require special magnetic fields, with field lines arranged in a very specific way - such as a magnetic field that is relatively constant in one direction, but which varies in strength in another direction."

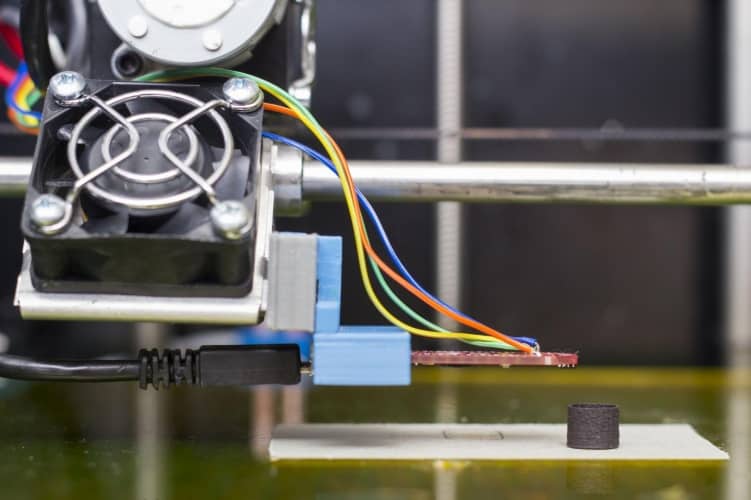

The system, described in the journal Applied Physics Letters, uses specially produced filaments of magnetic micro granulate, which is held together by a polymer binding material. During the printing process, the material is heated and applied point-by-point using a nozzle. The result is a three-dimensional object composed of roughly 90 per cent magnetic material and 10 per cent plastic.

However, this end product is not yet magnetic, as the granulate is deposited in an unmagnetised state. A strong external magnetic field must be applied to the object after it is printed in order to convert it to a permanently magnetised state.

"This method allows us to process various magnetic materials, such as the exceptionally strong neodymium iron boron magnets," said Süss. "Magnet designs created using a computer can now be quickly and precisely implemented - at a size ranging from just a few centimetres through to decimetres, with an accuracy of well under a single millimetre."

Using additive manufacturing also allows a combination of magnetic materials to be incorporated within the one object, something that could allow a smooth transition between strong and weak magnetic forces. According to Süss, the ability to customise both the shape and make-up of magnets could unlock huge potential.

"Now we will test the limits of how far we can go,” he said, “but for now it is certain that 3D printing brings something to magnet design which we could previously only dream of."

JLR teams with Allye Energy on portable battery storage

This illustrates the lengths required to operate electric vehicles in some circumstances. It is just as well few electric Range Rovers will go off...