Norwegian company EnSol AS has patented the concept and seeks to develop it commercially by 2016.

The company is now working with engineers at Leicester University’s Department of Physics and Astronomy to scale up the process of depositing gold nanoparticle cells less than 10nm in size in a transparent composite matrix.

Chris Binns, a professor of nanotechnology at Leicester, said this material could one day coat areas such as roofs of cars or aircraft wings.

‘The first application you think of though is coating windows in buildings,’ he said, adding the glass would have a slight tinting.

‘There is power to burn with windows because even in the UK you’ll easily get 500W/m2. If you think of a square metre in a typical office building, it’s absolutely massive.’

Binns explained that the technology differs to traditional solar cells because it is based on metal nanoparticles, which have more favourable optical properties to silicon.

‘They have a very intense optical absorption, which is exactly matched to the peak of the sun’s spectrum just by coincidence,’ he said.

The inventor of the technology, Phil Denby, who is a co-founder of EnSol, admits the efficiency of the metal nanoparticle cells have only yet been demonstrated as proof of concept.

‘We’re struggling with funding, as all research projects are, so we haven’t got to a stage where we can compete against any existing cell technology,’ he said. ‘But the way the cell is fabricated means we’re not dependent on the bandgap energy like silicon solar cells. So potentially we could get up to the thermodynamic limit of solar cell technology. Rather than 30 per cent with silicon, we could get up to 80 per cent efficiency.’

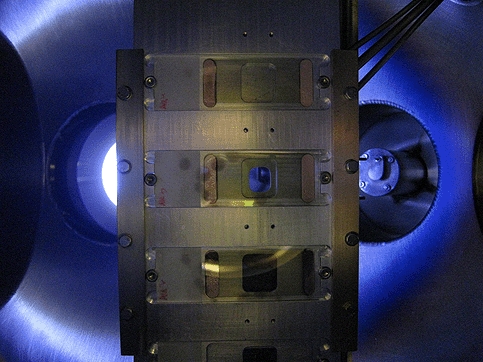

EnSol has invested in equipment at Leicester University to produce small amounts of the material for prototypes. The experimental facility will be designed to produce photovoltaic cells with an active area in excess of 40 x 4 mm deposited onto standard glass substrates. These prototype cells will subsequently be characterised and tested.

Binns said EnSol’s photovoltaic technology could one day prove to be less expensive than silicon cells to manufacture with potential ‘spray-on’ techniques.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...