Tony Pixton: Chief executive, Advanced Propulsion Centre

Education

- 1976 MEng in Automotive Engineering and Design

- 1985 Completed graduate course in Automotive Manufacturing Programme at INSEAD in Fontainebleau, France

Career

- 1999–2003 Director at Ford Motor Company, leading an international team developing a medium four-wheel drive platform

- 2003–2006 Platform director at Volvo, leading a team to deliver a large four-wheel drive platform

- 2006–2009 Executive director at Ford, leading integration of global product development activities and advising chairman

- 2009–2012 Representative director and senior managing executive officer, Mazda Motor Corp

- 2012–2013 founded and operated own consultancy

- 2014–2015 appointed chief executive for launch of Advanced Propulsion Centre

- 2015 Remains on APC board when he is succeeded by Ian Constance as chief executive

The Advanced Propulsion Centre (APC) is housed in one of the many smartly modern buildings on Warwick University’s campus, next to (but not physically or organisationally attached to) the bulky grey oblong of Warwick Manufacturing Group, and a small vegetation-packed pond patrolled by ill-tempered geese. Within, the bulk of the ground floor is taken up by a showcase centre, opened two months ago, which sets out on movable fabric panels the goals and procedures of the APC, punctuated by exhibition-style stands housing examples of technologies the centre has helped develop.

”We provide support for companies who maybe had a project funded by InnovateUK but need to go from a one- or two-off prototype to a production-ready product.

Tony Pixton, who has led the opening and establishment of the APC over the past 18 months and will shortly step down as chief executive while remaining on the board, is a hugely experienced figure at the high levels of the automotive sector and a knowledgable engineer in his own right. The roots of the centre, he explained, showing me around the exhibition space, go back to the efforts of the Labour government, headed by then-business secretary Peter Mandelson, to bolster the automotive sector, which then had several large companies with facilities here but a hollowed-out supply chain, a legacy of industrial decline in the 1970s and 1980s. The idea, said Pixton, was to develop technology areas where the UK had a lot of potential, both in terms of expertise and in market growth, and use that to help businesses become more established and also attract the large multinational players to choose the UK as the location for their R&D and technology development.

“The National Automotive Innovation Growth Team did a study that looked at the future of the UK automotive industry in 2009,” Pixton explained. “That resulted in a report whose key recommendations included the formation of the Automotive Council to bring government and industry together.” One of the first results of this were a set of industry roadmaps, including a whole suite of them that addressed the area of vehicle propulsion: not just the traditional internal combustion engine (ICE) powertrain but taking in the development of electric and hybrid systems as well. “This identified strategic technologies that the UK could potentially lead the world in, because of the strengths of the research base here and the background in manufacturing.”

The UK’s strengths in many of these areas was already apparent. “For energy storage, lithium batteries were invented in Oxford and they are still very strong there in battery chemistry. We have numerous well-established centres of excellence in ICE; Nottingham University is one of the world centres for power electronics; and in lightweighting, carbon fibre was pioneered in the UK thanks to our capabilities in motorsport: McLaren built the first carbon-fibre Formula One chassis.”

”Global players, even the ones that are based in the UK such as Jaguar Land Rover, can put their R&D wherever it makes sense to do it, and they can put their manufacturing wherever they want to as well. The best way to make sure they come here is to have technical capability

Developing these areas was, and is, seen as a way of anchoring capability in the UK. “Clearly that’s good for the economy, but the Automotive Council saw this as a matter of competitive edge,” Pixton said. “Global players, even the ones that are based in the UK such as Jaguar Land Rover, can put their R&D wherever it makes sense to do it, and they can put their manufacturing wherever they want to as well. The best way to make sure they come here is to have that technical capability; that’s even more important than financial incentives — although they play their part too.”

Hence the formation of the APC in 2014, acting as a hub for work in the four technical areas mentioned above. The main goal of the centre is to work with companies developing propulsion-linked technologies and help them to bridge the dreaded ‘valley of death’ between developing a prototype and making this into a product they can manufacture in the numbers that the automotive industry needs from their suppliers – tens or hundreds of thousands per year, under tight cost control and meeting stringent quality standards. “We provide support for companies who maybe had a project funded by InnovateUK but need to go from a one- or two-off prototype to a production-ready product. InnovateUK does a fantastic job but only supports development of concepts from research bench to prototype,” Pixton explained. “In terms of manufacturing, we go from a state where you have a basic feasibilty study of materials and the manufacturability, but you don’t have a process. We go up to having a production-line design worked out and ready to put in a pilot line to build pre-production samples.”

Often, the companies APC works with are SMEs or university spin-outs, but not always. “Sometimes, it’s surprisingly large companies who developed technology so new they haven’t been able to develop a compelling enough business case to push it through the development process internally. We’ve been able to provide assistance with structuring the project with a consortium of companies then provide funding through the government to bridge the gap.”

One way this is done is through competitions. “We run competitions twice a year, we have £1bn to spend on them over 10 years, half from government in cash, half from industry in kind. We get applications that fit the technologies and are consistent with the roadmaps. So far we’ve funded 10 projects through three competitions, with a fourth one just closed and going through the independent assessment process. Those 10 projects have directed £174m-worth of investment in the UK, with maybe 4,500 jobs involved in those projects. We think 12 million tonnes of CO2 will be saved by these 10 projects over a 10-year cycle. That’s equivalent to taking 6,000 conventional cars off the road.”

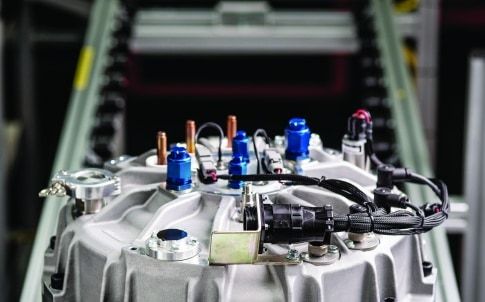

One example of such a project is the Gyro-drive flywheel energy recovery system, derived from the KERS flywheel system developed by Williams F1. The company worked with GKN, which subsequently bought the technology, to link the flywheel to energy storage, power electronics and a motor, allowing it to capture, store and release braking energy. It’s particularly suited to the stop-start motion of buses, and, according to Pixton, can cut fuel consumption by some 25 per cent on most routes. “This was demonstrated by GKN and Williams as a system with potential for buses, but it didn’t go any further until GKN applied for one of our project fundings, and we’ve supported its development into a retro- or OE-fit for buses. Alexander Dennis is part of the consortium. It shows how we’re building links between motorsport and manufacturing. It builds prototypes, races them and scraps them; we turn them into products that can be manufactured.”

Another way APC works is to develop SMEs, sometimes very small ones, into organisations equipped to run projects with big players. “We have a specific programme for small companies called the technology development accelerator programme [TeDAP],” Pixton explained. “We’e putting 10 SMEs through a three-stage programme to get their technologies to a prototype concept that can go into a larger project with a Tier One or OEM. It helps them understand their product and develop a business plan.”

The alignment of competitions with the roadmaps is crucial. “We’re trying to ensure our projects fill in these streams of activity,” Pixton said. “The competitions are designed to ensure the right technologies are being worked on at the right time.”

APC acts as an organisational hub, and is establishing ‘spokes’ in its various technology areas. These are intended to act as centres of excellence and coordinating points that companies can consult if they need expertise in that area for a project. So far, there are three: power electronics at Nottingham University; electrical energy storage at Warwick, and, due to open next March, digital engineering and test at Loughborough University’s graduate study centre on the Olympic Park in London.

Summing up the APC’s role, Pixton said: “Our role is to help rebuild the supply chain, and we focus on that in our projects. We insist that a UK-based SME is involved in every project. Even when multinationals are involved, the bulk of the work has to be in the UK to anchor the capability for the next project. That way, new projects can flow in, because the capability will be there. Is it having an effect on the supply base? Clearly it is. Is it good enough yet? Nowhere near. We have a long road to work on.”

Hybrid: GKN and Williams’ Gyro-drive flywheel technology

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...