It’s fair to say that the environment and the aerospace industry are not the easiest of bedfellows.

But while many claim that the continued growth of aviation is simply incompatible with global emissions targets, others are more optimistic. And the decision by US jet engine manufacturer Pratt & Whitney to combine responsibility for the environment with responsibility for technology indicates that, at the very least, industry is taking the issue seriously.

According to the man in the hot seat, Dr Alan Epstein — the firm’s vice-president of technology and environment — reducing emissions while advancing aerospace technology are actually mutually beneficial goals. ‘Pratt realised that the environment would move from being an issue of compliance to being something that differentiates the products and defines the future,’ he told The Engineer.

Earlier this year, we spoke to Rolls-Royce’s technology chief Prof Ric Parker: in some respects Epstein’s UK equivalent. Parker optimistically claimed that some of the industry’s biggest technical leaps are yet to come. But if he was positive on aviation’s ability to simultaneously grow and reduce its environmental impact, Epstein is bullish, and suggested that the ACARE targets — the European goals to halve CO2 and noise emissions by 2020 — are, if anything, not ambitious enough. ‘I think some of the estimates of efficiency potential are modest; we as an industry can probably do better. The ACARE goals to me are readily achievable.’

Indeed, Epstein — a former professor of aeronautics at MIT — believes that the company’s latest jet engine, the Purepower PW1000G, will meet the ACARE goals seven years early when it enters service in 2013. ‘We’re ahead of the game,’ he said, ‘it cuts NOx by 60 per cent compared to current engines; fuel consumption of the engine alone is 15 per cent better and noise is 20dB less, which if you look at impact on the ground is reduced by three-quarters.’

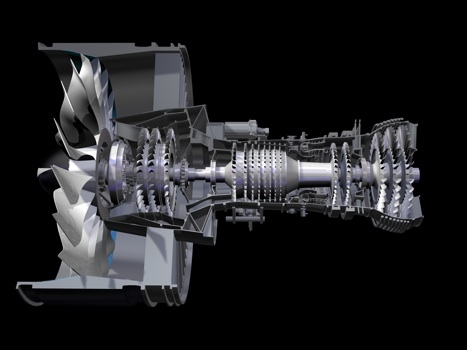

The new engine, which will make its commercial debut on the Mitsubishi regional jet and Bombardier’s C-Series, is the world’s first commercial geared turbofan.

Successive generations of turbofans — the engines that power most civil airliners — have seen the introduction of bigger and bigger fans in an effort to improve efficiency by boosting the bypass ratio: the ratio of the mass of air routed around the turbine to the mass of air that passes through it. The problem is that these fans have now reached a size where the weight of the fan and the bulk of the casing start to eat into efficiency.

Geared turbofans offer a potential solution to this problem by breaking the direct connection between turbine and fan using a series of gears. Therefore, instead of having the fan and turbine spinning at the same speed, the fan can turn slower than the turbine. This means the turbine can be very small and very fast, while the fan can be much larger, slower and, because it is the fan that produces most of the noise of the engine, quieter.

‘There will never be a big open rotor airplane; they make too much noise. If you’re concerned about aviation’s growth, open rotors are the solution, because they won’t grow!’

Alan Epstein, Pratt & Whitney

Epstein bristles with pride while describing the 30,000HP gear at the heart of the Purepower engine, a highly complex system that has been the big stumbling block to the technology in the past. ‘We had a lot of trouble convincing people that such a gear could exist,’ he said. ‘It’s about 20in in diameter and weighs a little more than 100kg. It’s the size of an auto-wheel with the power of a frigate going through it and it’s much better than 99 per cent efficient.’

So far the engine has been subjected to endurance testing equivalent to more than 20,000 hours of service, as well as 120 hours in flight, and despite some unplanned ‘exotic’ manoeuvres carried out by the test pilots, the gears performed well. ‘We took the gear apart afterwards and it didn’t deteriorate at all,’ adds Epstein. ‘We’ve done the equivalent of about 20 years life on the gears and they still show no wear.’

He also suggested that rather than being overly complex, as has been claimed in the past, geared fans are potentially far cheaper to manufacture and maintain. ‘The gear takes out six stages of nickel super alloy and titanium. The weight and cost of the gear is the same as the weight and the cost of one stage, so it costs less to manufacture. Plus, there’s 1,400 fewer airfoils so it’s cheaper to maintain — I think all engines will have gear, it’s obvious that the gear is the future.’

In contrast, Epstein is somewhat less enthusiastic about the prospect for open rotor engines, described by Rolls-Royce’s Parker as ‘the only step-change technology we can see today’.

‘There will never be a big open rotor airplane; they make too much noise,’ said Epstein. ‘If you’re concerned about aviation’s growth, open rotors are the solution, because they won’t grow!’

Instead, Epstein anticipates continuing developments in geared turbofan technology, and he believes there’s plenty of scope for improvements. ‘The current Purepower engines are pretty conservative in their design,’ he added, ‘they’re a new concept, you want them to be ultra reliable coming out of the box, so the engineers are fully constrained from some of their more advanced enthusiasm.’ One of the most important factors in the development of higher and higher bypass ratio engines will be the emergence of new advanced materials for the hot section of the engine. ‘We’re now up to compression ratios of 40-50:1, meaning before you get to a combustor you’re melting rock, you’re running the turbines now at multi-thousand Kelvin so the blades are white hot.’

Epstein said that future hot-section materials currently under the spotlight include ceramics, nanomaterials and new advanced alloys.

He also expects man-made fuels to play a key role in the medium term. ‘By 2020 I would expect three per cent of the fuel available to be a drop-in biofuel,’ he added, ‘I think aviation is the ideal place for biofuels because there’s no alternative, you can’t make an electric airplane.’

Epstein believes that this demand could drive a series of innovations in the biofuel production industry. ‘We need technology for growing more fuel from less space — for jet fuel from soya beans you get about 100 gallons per acre per year and that’s equivalent to about 0.05 per cent efficiency.’

Returning to the question of whether developments in these areas can reconcile aviation growth with global emissions targets, Epstein is unequivocal. ‘One of my jobs is to make it happen. Since the invention of the jet engine we’ve improved airplane fuel burn by about 2.5 per cent a year on average. I think we can continue to do that with suitable investments. Technology hasn’t slowed down in aero engines — we’re a voracious producer and consumer of it and there’s as much to be had in the next 40 years as we’ve got in the last 40 years. And it’s fun for engineers.’

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...